Choosing between diamond embossed and flat aluminum coil can be daunting. Each type offers unique benefits and applications. In this post, you'll learn about the features, advantages, and best uses for each. Understand how to select the right aluminum coil for your needs.

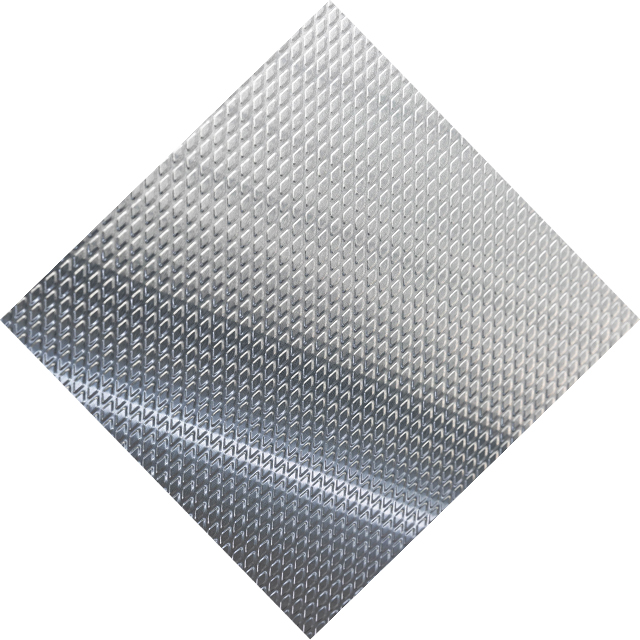

Understanding Diamond / Rhombus Embossed Aluminum Coil

What is Diamond / Rhombus Embossed Aluminum Coil?

Diamond or rhombus embossed aluminum coil is a type of aluminum coil featuring a raised diamond-shaped pattern on its surface. This textured aluminum coil sheet enhances both functionality and aesthetics. Unlike flat aluminum coil rolls, the embossed pattern provides increased rigidity and slip resistance, making it ideal for applications requiring durability and safety. Commonly, aluminum coil siding, aluminum coil fascia, and aluminum trim coil pvc coated products utilize this embossed design for added strength and visual appeal.

Manufacturing Process

The production of diamond embossed aluminum coil begins with selecting suitable aluminum alloys, often from popular series like 1050, 3003, or 5052. The aluminum coil is first rolled to the desired thickness using an aluminum coil brake. Then, it passes through embossing rollers engraved with the diamond pattern. The immense pressure permanently imprints the rhombus texture onto the aluminum surface. This embossing process slightly work-hardens the metal, improving its strength without significantly increasing weight.

Post-embossing, the aluminum coil may undergo additional surface treatments such as anodizing by aluminum coil anodizing corp or applying pvc coated trim coil layers. These treatments enhance corrosion resistance, wear resistance, and aesthetic qualities. Textured aluminum trim coil options like wood grain aluminum trim coil or pvc coated aluminum trim coil offer further customization for decorative or functional needs.

Key Characteristics and Benefits

Enhanced Rigidity: The embossed pattern increases structural strength, allowing thinner gauges to perform better under stress.

Slip Resistance: The diamond texture provides excellent grip, making it suitable for flooring, ramps, and walkways.

Reduced Glare: The textured surface diffuses light, minimizing reflections and improving visual comfort.

Durability: Combined with anodizing or coating, embossed aluminum coils resist corrosion and wear effectively.

Aesthetic Appeal: The diamond pattern adds a distinctive look, useful in architectural and industrial design.

Lightweight: Maintains aluminum’s natural lightness, facilitating easier handling and installation.

Easy Maintenance: The surface is simple to clean and hides minor scratches or blemishes.

Diamond embossed aluminum coil is a versatile material used in various industries, from construction to transportation. Its combination of functional and decorative qualities makes it a preferred choice among aluminium coil suppliers for applications like aluminum coil siding, aluminum coil fascia, and specialty aluminum coil sheet products.

Tip: When selecting embossed aluminum coil for your project, consider the alloy type and surface finish to balance strength, corrosion resistance, and aesthetic needs effectively.

Exploring Flat Aluminum

Definition and Properties of Flat Aluminum

Flat aluminum refers to aluminum coil or sheet with a smooth, untextured surface. Unlike embossed aluminum coil, flat aluminum coil rolls provide a uniform, sleek finish without raised patterns. This type of aluminum coil sheet is often produced using an aluminum coil brake to achieve precise thickness and flatness. Flat aluminum typically comes in various alloys such as 1050, 3003, and 5052, offering a balance of strength, corrosion resistance, and formability. Its flat surface makes it ideal for applications requiring clean, polished looks or easy coating, including pvc coated aluminum trim coil and aluminum coil siding.

Flat aluminum’s key properties include:

Smooth Surface: Ideal for painting, coating, and anodizing processes by aluminum coil anodizing corp.

Lightweight: Maintains aluminum’s natural lightness for easier handling and installation.

Corrosion Resistance: Naturally resistant to rust, enhanced further with coatings like pvc coated trim coil.

High Reflectivity: Suitable for reflective surfaces or mirror finishes.

Versatility: Available in various thicknesses and widths tailored by aluminium coil suppliers.

Typical Applications

Flat aluminum coil is widely used in industries where a smooth surface is essential. Common applications include:

Architectural Panels: Aluminum coil siding and aluminum coil fascia benefit from flat aluminum for a clean, modern look.

Automotive Components: Flat aluminum sheets serve as body panels and trim due to their formability.

Consumer Goods: Used in appliances, packaging, and electronic casings.

Signage and Advertising: Flat surfaces allow for easy printing and coating.

Fabrication: Ideal for bending and forming with tools like aluminum coil brakes.

Additionally, flat aluminum serves as a base for textured aluminum trim coil or wood grain aluminum trim coil when decorative finishes are required.

Advantages of Flat Aluminum

Flat aluminum offers several benefits that make it a preferred choice in many scenarios:

Cost-Effective: Generally less expensive than embossed options, making it suitable for budget-conscious projects.

Ease of Processing: Its smooth surface allows for straightforward cutting, bending, and machining.

Customizable Finishes: Compatible with various coatings, including pvc coated aluminum trim coil and anodizing, enhancing durability and aesthetics.

Lightweight and Strong: Provides a good strength-to-weight ratio, essential for structural and decorative uses.

Uniform Appearance: Ideal when a sleek, polished look is desired without texture or embossing.

Compatibility: Works well with other materials and finishes, facilitating integration into complex assemblies.

Flat aluminum coil stock prices tend to be more stable due to simpler manufacturing processes compared to embossed variants.

Tip: When selecting aluminum coil for projects prioritizing smooth finishes or intricate coatings, flat aluminum coil offers superior surface uniformity and ease of customization.

![diamond11 diamond11]()

Comparative Analysis: Diamond / Rhombus Embossed vs Flat Aluminum

Performance and Durability

Diamond or rhombus embossed aluminum coil offers enhanced rigidity due to its textured surface. The embossing process work-hardens the aluminum coil sheet, increasing strength without adding weight. This makes embossed aluminum coil rolls ideal for applications demanding durability and structural integrity, such as aluminum coil siding and aluminum coil fascia. The raised pattern also provides superior slip resistance, crucial for flooring and industrial walkways.

Flat aluminum, in contrast, has a smooth surface, which while aesthetically clean, does not provide the same level of mechanical strength or anti-slip properties. However, flat aluminum excels in applications requiring uniform surfaces, such as in architectural panels or consumer goods, where ease of coating with pvc coated aluminum trim coil or anodizing treatments by aluminum coil anodizing corp is important.

Cost Implications

Typically, flat aluminum coil stock prices are lower than embossed variants. The embossing process adds manufacturing complexity and time, which can increase costs. For budget-sensitive projects, flat aluminum coil sheets present a cost-effective solution while still offering excellent corrosion resistance and versatility.

Embossed aluminum coil, especially those with specialized patterns like diamond or rhombus, may carry a premium but deliver added value through durability and safety features. Additionally, coatings such as pvc coated trim coil or wood grain aluminum trim coil can influence costs depending on finish and performance requirements.

Suitability for Various Applications

Embossed aluminum coil is well-suited for industrial and commercial uses where grip, wear resistance, and strength are priorities. Applications include aluminum coil siding on ramps, walkways, and vehicle floors, where safety is paramount.

Flat aluminum coil is preferred for applications emphasizing aesthetics and smooth finishes, such as aluminum coil fascia and decorative architectural elements. It is also favored in lightweight structures and projects requiring intricate bending or forming using aluminum coil brakes.

Visual and Aesthetic Considerations

The embossed diamond or rhombus pattern adds texture and visual interest, often used decoratively or to reduce glare by diffusing light. This makes embossed aluminum coil a popular choice for textured aluminum trim coil or pvc coated aluminum trim coil products where both function and style matter.

Flat aluminum provides a sleek, polished look, ideal for modern architectural designs or where a uniform surface is desired for painting or anodizing. It supports a wide range of coatings, including color-coated finishes, enhancing its decorative potential.

Environmental Impact

Both embossed and flat aluminum coils maintain aluminum’s inherent recyclability and corrosion resistance. Embossed aluminum’s enhanced durability can extend product lifespan, potentially reducing replacement frequency and resource consumption. Flat aluminum’s simpler manufacturing process may result in slightly lower energy use during production.

Choosing between embossed and flat aluminum coil should consider the entire lifecycle, balancing performance benefits with manufacturing and maintenance impacts.

Tip: For projects requiring safety and durability, opt for diamond embossed aluminum coil; for smooth, cost-effective surfaces with versatile finishing options, flat aluminum coil is the better choice.

When to Use Diamond / Rhombus Embossed Aluminum Coil

Applications Requiring Enhanced Grip

Diamond or rhombus embossed aluminum coil is an excellent choice when enhanced grip and slip resistance are critical. Its raised pattern creates a textured surface that significantly reduces the risk of slipping, making it ideal for flooring, ramps, stair treads, and walkways. For example, aluminum coil siding on industrial platforms or vehicle floors often employs embossed aluminum coil to ensure safety in wet or oily conditions. The textured aluminum trim coil also works well in areas where foot traffic demands durable, anti-slip surfaces.

Decorative and Aesthetic Uses

Beyond functionality, diamond embossed aluminum coil offers decorative appeal. The unique rhombus pattern adds depth and character to architectural and interior design elements. It’s often used in aluminum coil fascia and aluminum coil siding where visual interest is desired without sacrificing durability. Coatings such as pvc coated trim coil or wood grain aluminum trim coil can further enhance aesthetics while protecting the surface. Textured aluminum trim coil options provide designers with versatile finishes that combine form and function, making embossed aluminum coil a popular choice for both commercial and residential projects.

Industrial and Commercial Settings

In industrial and commercial environments, the durability and strength of diamond embossed aluminum coil come into full play. The embossing process increases rigidity, reducing deformation under heavy loads while maintaining lightweight properties. This makes it suitable for protective panels, equipment housings, and storage compartments. It also withstands harsh conditions, especially when paired with anodized finishes from aluminum coil anodizing corp or protective coatings like pvc coated aluminum trim coil. The ability to customize embossing patterns and finishes allows aluminium coil suppliers to meet specific industry requirements efficiently.

Tip: For projects requiring safety, durability, and a distinctive look, choose diamond or rhombus embossed aluminum coil to combine anti-slip performance with decorative appeal.

When to Opt for Flat Aluminum

Situations Favoring Flat Surfaces

Flat aluminum coil is the go-to choice when a smooth, uniform surface is essential. Its sleek, untextured finish makes it perfect for applications like aluminum coil siding and aluminum coil fascia, where a clean, modern look is desired. For example, architectural panels and exterior cladding benefit from flat aluminum’s ability to provide a consistent appearance that easily accepts coatings such as pvc coated aluminum trim coil or anodizing treatments by aluminum coil anodizing corp. When you need to print or apply decorative finishes like wood grain aluminum trim coil, flat aluminum coil sheet offers an ideal base due to its flawless surface.

Cost-Effective Solutions

Flat aluminum coil stock prices are generally more affordable than embossed aluminum options. The simpler manufacturing process—primarily rolling and cutting using tools like an aluminum coil brake—keeps production costs lower. This cost advantage suits projects with tight budgets that still require aluminum’s corrosion resistance and lightweight benefits. For instance, large-scale construction projects or consumer goods manufacturers often select flat aluminum coil rolls to optimize expenses without compromising material quality. Moreover, flat aluminum’s compatibility with various coatings, including pvc coated trim coil, allows customization without significant cost increases.

Use in Lightweight Structures

Flat aluminum’s excellent strength-to-weight ratio makes it ideal for lightweight structures. It’s easier to cut, bend, and shape, which is critical in applications needing intricate fabrication or delicate forms. Industries such as automotive, aerospace, and electronics rely on flat aluminum coil sheets for components where minimizing weight is crucial. The material’s formability also supports efficient manufacturing with aluminum coil brakes and other processing equipment. Additionally, flat aluminum’s smooth surface facilitates bonding and assembly with other materials, enhancing structural integrity without adding bulk.

Tip: For projects demanding smooth finishes, budget-friendly options, or lightweight fabrication, flat aluminum coil provides the optimal balance of cost, aesthetics, and performance.

Conclusion

Diamond embossed aluminum coil offers enhanced grip and durability, ideal for safety-critical applications. Flat aluminum provides a smooth surface suitable for aesthetic and lightweight projects. Yuqi Metal provides high-quality aluminum coil products, ensuring safety and visual appeal. Future trends may see increased demand for both types, with innovations in coating and fabrication enhancing their versatility and environmental benefits. As the industry evolves, Yuqi Metal's expertise and product offerings will continue to provide value and meet diverse customer needs.

FAQ

Q: What are the main differences between diamond embossed and flat aluminum coil?

A: Diamond embossed aluminum coil features a textured surface that enhances rigidity and slip resistance, making it ideal for applications like aluminum coil siding and industrial flooring. Flat aluminum coil, on the other hand, offers a smooth surface, suitable for projects requiring sleek aesthetics and easy coating, such as pvc coated aluminum trim coil.

Q: When should I choose diamond embossed aluminum coil over flat aluminum?

A: Opt for diamond embossed aluminum coil when you need enhanced grip and durability, such as in industrial settings or for aluminum coil fascia with a decorative touch. It’s excellent for high-traffic areas requiring slip resistance.

Q: Are flat aluminum coil stock prices generally lower than embossed ones?

A: Yes, flat aluminum coil stock prices are typically lower due to simpler manufacturing processes. This makes flat aluminum a cost-effective choice for projects needing smooth surfaces and easy customization, like pvc coated aluminum trim coil.

Q: Can I use flat aluminum coil for decorative applications?

A: Absolutely. Flat aluminum coil is ideal for decorative applications where a sleek, uniform appearance is desired. It serves as a great base for coatings like wood grain aluminum trim coil, offering both aesthetic appeal and functionality.