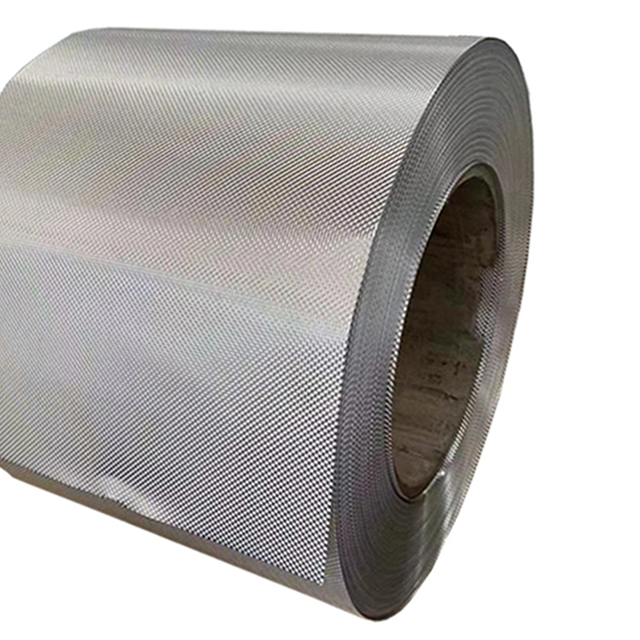

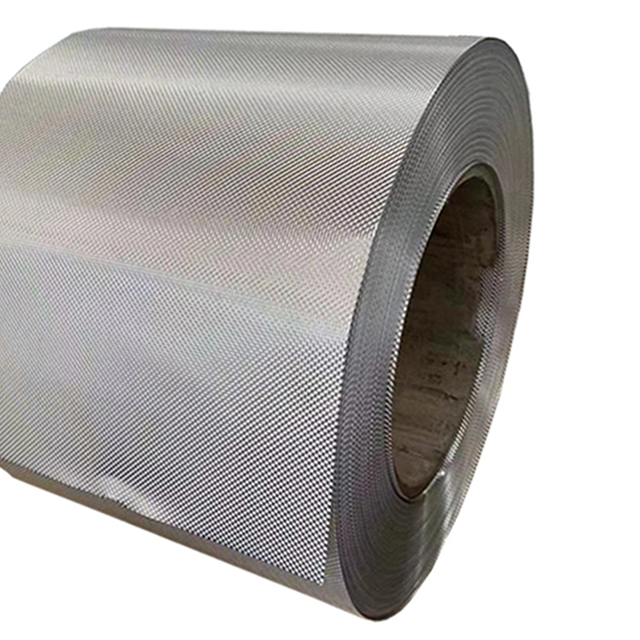

Have you ever wondered how aluminum coil can be both visually stunning and highly functional? Hemisphere embossing transforms aluminum coil into a material with unique aesthetic and practical benefits. In this article, you'll learn about the advantages of hemisphere embossing aluminum coil, its applications, and how to choose the right type for your needs.

Understanding Hemisphere Embossing Aluminum Coil

What is Hemisphere Embossing?

Hemisphere embossing is a specialized surface treatment applied to aluminum coil that creates a pattern of small, uniform convex hemispherical shapes across the metal’s surface. These tiny, pearl-like bumps increase the coil’s surface area and add a unique texture that is both visually appealing and functional. Often called “pearl pattern aluminum,” this embossing style enhances the aluminum coil’s strength and heat dissipation capabilities without adding significant weight.

Manufacturing Process of Embossed Aluminum Coil

The production of hemispherical embossed aluminum coil starts with high-quality aluminum coil stock, commonly from the 1000 series (such as alloys 1050, 1060, and 1100). The coil undergoes a rolling process where it is passed through embossing rollers equipped with hemispherical patterns. These rollers press the pattern into the aluminum surface under controlled pressure, ensuring uniform depth and shape of the embossing.

Key steps include:

Selection of Alloy and Temper: Choosing the right aluminum grade and temper (e.g., O, H14) based on application needs.

Rolling and Embossing: The coil is rolled and embossed using high-strength embossing machines that minimize deformation.

Surface Treatment: After embossing, the coil may receive additional finishes such as anodizing, painting, or coating to enhance corrosion resistance and aesthetics.

Cutting and Packaging: The embossed coil is slit or cut to size, then packaged carefully to avoid damage during transport.

This process results in aluminum coil that is lightweight, durable, and thermally efficient, ideal for heat shield applications and decorative uses.

Common Alloys Used in Hemisphere Embossing

The most frequently used aluminum alloys for hemisphere embossing include:

| Alloy | Characteristics | Typical Uses |

| 1050 | High purity (99.5%+), excellent corrosion resistance, great reflectivity | Heat shields, decorative panels |

| 1060 | Similar to 1050 but with slight mechanical property variations | Automotive interiors, kitchen equipment |

| 1100 | Excellent thermal conductivity and formability | Food containers, building materials |

| 3003 | Contains manganese, higher strength and good corrosion resistance | Storage boxes, air conditioning parts |

| 5052 | Magnesium content for superior strength and corrosion resistance | Marine applications, industrial panels |

These alloys provide a balance of machinability, durability, and thermal performance suited for embossed aluminum coil products.

Tip: When selecting hemispherical embossed aluminum coil, consider the alloy’s thermal conductivity and corrosion resistance to match your application’s environmental and functional demands.

Aesthetic Advantages of Hemisphere Embossing Aluminum Coil

Visual Appeal and Design Flexibility

Hemisphere embossing transforms plain aluminum coil surfaces into visually captivating materials. The small, uniform hemispherical patterns create a distinctive pearl-like texture, elevating the aluminum coil’s aesthetic appeal. This embossing technique offers remarkable design flexibility, allowing manufacturers to customize patterns to fit various architectural or decorative themes. Whether used as aluminum sheet coil for interior panels or painted aluminum coil for colorful facades, the embossed surface adds depth and character that flat aluminum coil stock cannot match.

This design flexibility extends to finishes as well. Embossed aluminum coils can be anodized aluminum coil or coated aluminum coil, providing options for color, gloss, and durability. For instance, wood grain aluminum coil with hemisphere embossing offers a natural look combined with metal’s strength, perfect for decorative trims or furniture accents like aluminum trim coil 24 x 50. The combination of embossing and surface treatment creates unique visual effects that appeal to designers and end-users alike.

Surface Texture and Pattern Options

The hemisphere embossing process allows for various pattern sizes and depths, catering to different functional and aesthetic needs. Small hemispherical patterns produce a fine, subtle texture ideal for sleek, modern designs. Larger hemispheres create a bold, tactile surface suitable for industrial or automotive applications. This versatility makes embossed aluminum coil popular among aluminum coil suppliers and distributors who serve diverse industries.

Common pattern options include single-sided embossing for decorative panels or double-sided embossing for enhanced structural properties. Patterns can be combined with other embossing styles such as diamond or stucco embossing to create hybrid textures. These options expand the possibilities for aluminium coil sheet applications, from architectural cladding to automotive heat shields.

Impact on Light and Shadow Play

One of the most striking aesthetic benefits of hemisphere embossing is its interaction with light. The convex hemispherical shapes scatter light in multiple directions, creating dynamic shadow patterns that change with viewing angle and lighting conditions. This effect adds visual interest and depth to surfaces, making them more engaging and attractive.

For example, an embossed aluminum coil used in building facades or interior walls can create a lively interplay of light and shadow throughout the day. This not only enhances the material’s appearance but can also contribute to energy efficiency by diffusing sunlight and reducing glare. Painted aluminum coil and anodized aluminum coil finishes further amplify this effect by adding color and reflectivity.

Tip: When selecting embossed aluminum coil, consider how the embossing pattern and surface finish will interact with natural and artificial light to maximize aesthetic impact in your project.

Functional Advantages of Hemisphere Embossing Aluminum Coil

Enhanced Heat Dissipation

Hemisphere embossing significantly improves the heat dissipation capabilities of aluminum coil. The tiny convex hemispherical patterns increase the surface area, allowing more efficient thermal exchange. This is especially beneficial in applications like automotive heat shields and HVAC systems, where managing heat is critical. Compared to flat aluminum sheet coil, embossed aluminum coil promotes faster heat transfer, protecting sensitive components from overheating. The enhanced thermal conductivity is a key reason why anodized aluminum coil and painted aluminum coil with hemisphere embossing are preferred for heat-sensitive environments.

Improved Structural Rigidity

The hemispherical embossing pattern adds structural strength to the aluminum coil without increasing its thickness. The embossed texture acts like a series of tiny reinforcements, boosting rigidity and resistance to bending or deformation. This means that aluminium coil sheet with hemisphere embossing can support higher loads and withstand mechanical stresses better than smooth sheets. This advantage is highly valued in architectural and automotive applications, where lightweight yet strong materials are essential. For example, aluminum coil stock with hemisphere embossing is commonly used in automotive interiors and industrial panels due to this improved durability.

Weight Reduction Benefits

Because hemisphere embossing enhances strength and heat dissipation, manufacturers can use thinner aluminum coil rolls without compromising performance. This leads to significant weight reduction, which is crucial in sectors like automotive and aerospace, where every gram counts. Lighter materials contribute to improved fuel efficiency and easier handling during installation. Additionally, thinner embossed aluminum coil requires less raw material, positively affecting aluminum coil price and overall project costs. Aluminum coil distributors often highlight these benefits to clients seeking cost-effective, high-performance materials.

Tip: When choosing embossed aluminum coil, consider hemisphere embossing to achieve superior heat management and structural strength while reducing weight, optimizing both performance and cost.

![Hemispherical4 Hemispherical4]()

Applications of Hemisphere Embossing Aluminum Coil

Automotive Industry Uses

Hemisphere embossing aluminum coil plays a vital role in the automotive sector, especially in heat shield applications. Its unique embossed surface improves heat dissipation, protecting sensitive engine and exhaust components from excessive temperatures. This lightweight material helps reduce overall vehicle weight, enhancing fuel efficiency and performance. Embossed aluminum coil stock made from alloys like 1050, 1060, and 1100 is commonly used for automotive heat shields, interior panels, and protective covers. Its corrosion resistance ensures durability in harsh environments, extending the lifespan of automotive parts.

Architectural and Decorative Applications

In architecture and interior design, hemisphere embossing aluminum coil offers both aesthetic and functional benefits. The embossed texture adds visual depth and a premium finish to aluminum sheet coil used in wall cladding, ceilings, and decorative panels. Coated aluminum coil and painted aluminum coil variants provide color options and weather resistance, while anodized aluminum coil enhances surface durability and sheen. Wood grain aluminum coil with hemisphere embossing mimics natural textures, making it popular for trims and furniture accents like aluminum trim coil 24 x 50. These materials are favored by aluminum coil suppliers for their versatility and design flexibility.

Industrial and Commercial Uses

Industries benefit from hemisphere embossing aluminum coil for its enhanced structural rigidity and heat management. The embossed pattern increases surface area, improving heat dissipation in HVAC systems, refrigeration units, and electronic enclosures. Aluminum coil distributors often supply embossed aluminum coil for industrial panels, storage boxes, and machinery covers. Its lightweight nature reduces handling costs and simplifies installation. Additionally, coated aluminum coil variants provide corrosion protection in demanding environments, while anodized finishes ensure long-term performance. For commercial gutters, aluminum gutter coil suppliers near me often recommend embossed coils for their durability and aesthetic appeal.

Tip: When sourcing hemisphere embossing aluminum coil, consider your application’s specific needs—whether automotive heat resistance, architectural aesthetics, or industrial durability—to select the right alloy, finish, and pattern from trusted aluminum coil suppliers.

Selecting the Right Hemisphere Embossing Aluminum Coil

Factors to Consider: Alloy, Thickness, Finish

Choosing the right hemisphere embossing aluminum coil starts with selecting the appropriate alloy. Common options include 1050, 1060, 1100, 3003, and 5052, each offering unique strength, corrosion resistance, and thermal properties. For example, 1050 and 1100 alloys provide excellent formability and reflectivity, making them ideal for decorative aluminum sheet coil applications. Meanwhile, 5052 offers higher strength and corrosion resistance, suited for more demanding environments.

Thickness is another key factor. Embossed aluminum coils typically range from 0.25 mm to 2.0 mm in thickness. Thicker coils offer greater durability and rigidity, beneficial for structural uses. Thinner coils are lighter and easier to shape, perfect for decorative or heat shield applications. The embossing pattern may also dictate minimum thickness to maintain pattern integrity.

Surface finish impacts both aesthetics and performance. Mill finish is raw and functional, while painted aluminum coil and coated aluminum coil provide color options and added protection. Anodized aluminum coil offers superior corrosion resistance and a sleek look. For a natural appearance, wood grain aluminum coil with hemisphere embossing can be selected, combining texture with design appeal.

Cost Considerations and Budgeting

Aluminum coil price varies based on alloy, thickness, embossing complexity, and finish. Pure aluminum alloys like 1050 tend to be more affordable, while specialty alloys or anodized finishes increase costs. Budgeting should balance initial price with long-term value. For instance, investing in anodized or coated aluminum coil can reduce maintenance and replacement expenses.

Purchasing from reputable aluminum coil suppliers ensures competitive pricing and quality. Bulk orders often lower unit costs. Keep in mind that thinner aluminium coil rolls with hemisphere embossing can reduce material use and weight, further optimizing costs without sacrificing performance.

Supplier Selection and Quality Assurance

Selecting reliable aluminum coil distributors is crucial. Look for suppliers with extensive experience in embossed aluminum coil products and a strong track record of quality assurance. They should offer detailed product specifications, including alloy composition, temper, thickness, and finish options.

Verify if the supplier provides customization services such as slitting, cutting, or specific embossing patterns. Also, inquire about certifications and quality control processes to ensure consistent product standards. Trusted suppliers often maintain ample aluminum coil stock to meet urgent demands.

Working with an aluminum coil anodizing corp or a supplier specializing in hemisphere embossing can provide technical support, helping you choose the best aluminum trim coil 24 x 50 or aluminum gutter coil suppliers near me for your project needs.

Tip: When selecting hemisphere embossing aluminum coil, prioritize alloy compatibility, thickness requirements, and finish options to optimize performance and cost, and always choose suppliers with proven quality assurance and customization capabilities.

Installation and Maintenance of Embossed Aluminum Coil

Installation Best Practices

Installing hemisphere embossing aluminum coil requires careful handling to preserve its embossed texture and finish. Before installation, ensure the aluminum coil stock is clean and free of debris. Use non-abrasive tools to avoid scratching the embossed surface, especially when working with painted aluminum coil or anodized aluminum coil finishes.

When cutting aluminum sheet coil or aluminum trim coil 24 x 50, use sharp blades designed for metal to maintain clean edges and prevent deformation. Allow for thermal expansion during installation, as aluminum expands and contracts with temperature changes. Proper fastening methods, such as using stainless steel screws or rivets, help avoid corrosion and maintain structural integrity.

For applications like gutters or roofing, sourced from aluminum gutter coil suppliers near me, ensure panels overlap correctly to prevent water ingress. Follow manufacturer guidelines on spacing and support to avoid buckling or warping of the aluminium coil roll.

Maintenance Tips for Longevity

Regular maintenance extends the life of embossed aluminum coil products. Clean painted aluminum coil and coated aluminum coil surfaces with mild detergents and soft cloths to remove dirt and pollutants without damaging the finish. Avoid harsh chemicals or abrasive cleaners that can degrade anodized aluminum coil coatings.

Inspect joints and fasteners periodically to ensure they remain secure and free from corrosion. For wood grain aluminum coil used in decorative trims, check for any peeling or fading and touch up with compatible paints if necessary.

Proper maintenance also includes protecting the embossed aluminum coil from prolonged exposure to harsh environments. Applying protective coatings or sealants can enhance corrosion resistance, especially for outdoor applications.

Common Challenges and Solutions

One common challenge during installation is managing the aluminum coil price while ensuring quality. Opting for lower-cost materials may lead to issues like reduced corrosion resistance or embossing defects. Working with trusted aluminum coil suppliers and distributors ensures you receive quality embossed aluminum coil that meets specifications.

Another challenge is handling the embossed surface without damaging its texture. Using protective films during transport and storage prevents scratches. When cutting or forming, specialized equipment designed for embossed aluminum coil reduces deformation.

Thermal expansion can cause buckling if not accounted for. Designing with appropriate expansion gaps and flexible fasteners mitigates this risk. For maintenance, avoid neglecting regular cleaning, as accumulated dirt can accelerate corrosion and degrade painted or coated surfaces.

Tip: When installing embossed aluminum coil, always allow for thermal expansion and use non-abrasive tools to protect the embossed texture and finish, ensuring long-lasting performance and appearance.

Conclusion

Hemisphere embossing aluminum coil offers aesthetic and functional benefits, including enhanced heat dissipation and structural rigidity. Future trends in embossed aluminum coil may focus on innovative designs and improved materials. Yuqi Metal provides high-quality embossed aluminum products that combine beauty and performance, making them ideal for various applications. Their commitment to quality ensures that customers receive valuable, durable products that meet diverse needs. Consider their offerings for reliable and efficient aluminum solutions.

FAQ

Q: What are the aesthetic benefits of hemisphere embossing on aluminum coil?

A: Hemisphere embossing on aluminum coil creates a unique pearl-like texture that enhances visual appeal and design flexibility. It allows for various finishes such as anodized or painted aluminum coil, offering options in color and gloss. This technique is popular for decorative applications like aluminum trim coil 24 x 50 and wood grain aluminum coil.

Q: How does hemisphere embossing improve the functional performance of aluminum coil?

A: Hemisphere embossing increases the surface area of aluminum coil, enhancing heat dissipation and structural rigidity. This makes embossed aluminum coil ideal for automotive heat shields and industrial panels. It allows for weight reduction without sacrificing strength, positively affecting aluminum coil price and overall project costs.

Q: What factors should be considered when selecting embossed aluminum coil?

A: Consider the alloy type, thickness, and surface finish when selecting embossed aluminum coil. Common alloys like 1050 and 5052 offer different strengths and corrosion resistance. Choose finishes such as anodized or coated aluminum coil for added durability. Reliable aluminum coil distributors can provide quality assurance and customization services.

Q: How can I ensure proper installation of embossed aluminum coil?

A: Use non-abrasive tools to protect the embossed texture during installation. Follow best practices for cutting and fastening, ensuring thermal expansion is accounted for. For applications like gutters, sourced from aluminum gutter coil suppliers near me, ensure panels overlap correctly to prevent water ingress.

Q: What maintenance practices prolong the lifespan of embossed aluminum coil?

A: Regularly clean painted or coated aluminum coil surfaces with mild detergents. Inspect joints and fasteners for corrosion. Protect the embossed aluminum coil from harsh environments with sealants. For wood grain aluminum coil, touch up any peeling or fading with compatible paints.