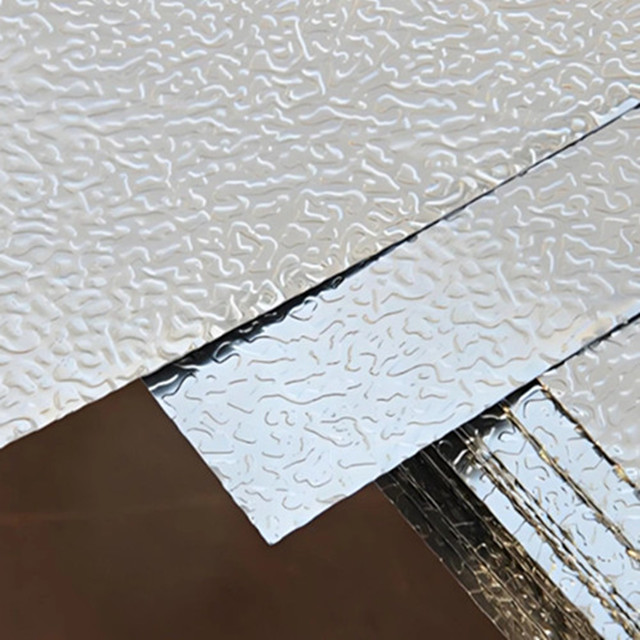

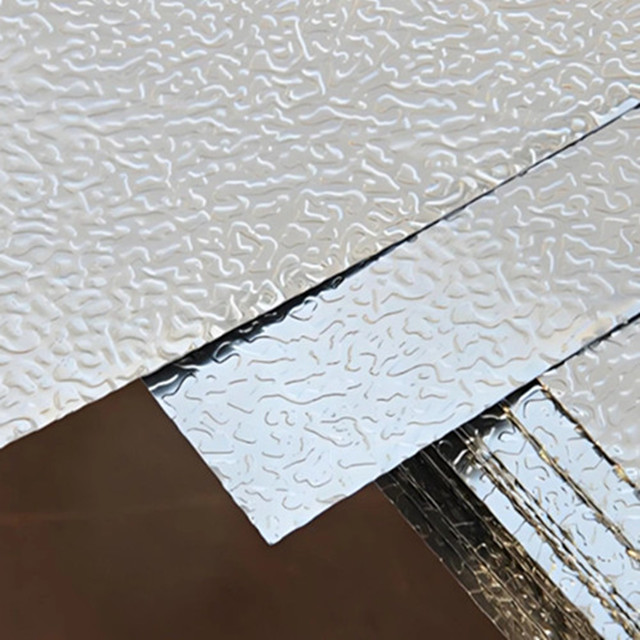

Ever wondered why certain aluminum coils have a unique textured surface? The answer lies in orange peel embossed aluminum coils. This distinctive texture enhances performance and aesthetics, making it a popular choice in various industries. In this post, you'll learn about its benefits, including improved anti-slip properties and corrosion resistance, and explore its applications in construction, automotive, and more.

Key Benefits of Orange Peel Embossed Aluminum Coil

Orange peel embossed aluminum coil stands out due to its unique textured surface, which offers several practical advantages. These benefits make it a preferred choice across various aluminium coil applications, especially where performance and aesthetics are both critical.

Enhanced Anti-Slip Properties

The orange peel texture creates a rough surface that significantly increases friction. This anti-slip characteristic is essential for safety in flooring, stair treads, and vehicle interiors. Compared to smooth aluminum coil sheets, the embossed surface reduces the risk of slipping, making it ideal for industrial and transportation uses.

Improved Corrosion Resistance

Aluminum naturally resists corrosion by forming a protective oxide layer. The embossing process enhances this effect by increasing surface area and allowing better adhesion of protective coatings. When combined with anodizing or coated aluminum coil finishes, it offers superior resistance against oxidation, moisture, and harsh environments. This durability extends the service life of products like aluminum coil siding and refrigeration equipment.

Lightweight and Durable

Like all aluminum coils, the orange peel embossed variant is lightweight, which eases handling and reduces structural loads. Despite its lightness, embossing work hardens the surface, improving strength and scratch resistance. This durability benefits applications in construction and automotive sectors, where materials must endure wear and tear without adding excessive weight.

Decorative Appeal

The distinctive orange peel pattern adds visual texture and depth, enhancing the aesthetic value of aluminum coil sheets. This decorative appeal suits architectural projects, home appliance manufacturing, and interior design. Moreover, painted aluminum coil or coated aluminum coil options allow customization in color and finish, blending functionality with style.

Good Thermal Conductivity

Aluminum's excellent thermal conductivity remains effective with the embossed texture. In fact, the increased surface area from embossing can improve heat dissipation. This property is particularly advantageous in refrigeration and HVAC systems, where efficient thermal transfer supports better energy performance.

Note: When sourcing orange peel embossed aluminum coil, consider suppliers that offer customization in thickness, coating, and alloy type to match your specific application needs.

Applications in Various Industries

Orange peel embossed aluminum coil is a versatile material widely embraced across multiple industries. Its unique texture and inherent properties make it an excellent choice for applications requiring durability, aesthetics, and performance. Let’s explore how this aluminum coil variant is utilized in different sectors.

Building and Construction

In the building industry, orange peel embossed aluminum coil is commonly used for exterior and interior decoration. Its textured surface adds a decorative appeal while providing practical benefits such as anti-slip flooring and wall cladding. This makes it ideal for aluminum coil siding, ceilings, and curtain walls. Additionally, its corrosion resistance and lightweight nature reduce maintenance costs and structural load. Coated aluminum coil options further enhance weather resistance, making it suitable for long-term outdoor exposure.

Refrigeration and HVAC Systems

The thermal conductivity of aluminum combined with the orange peel embossing improves heat dissipation, which is crucial in refrigeration and HVAC applications. It is widely used for inner panels, evaporators, and condenser covers in refrigerators and air conditioning units. The embossed texture increases the surface area, boosting thermal efficiency. Moreover, the corrosion resistance helps extend equipment lifespan in moist or cold environments. Painted aluminum coil finishes provide additional protection and aesthetic customization for visible parts.

Automotive and Transportation

Orange peel embossed aluminum coil finds extensive use in automotive manufacturing, especially for interior panels, flooring, and engine heat shields. Its anti-slip properties ensure safety on vehicle floors and loading platforms. The embossed surface also improves scratch resistance and durability without adding significant weight, which supports fuel efficiency. In transportation, it is used in trains, ships, and commercial vehicles for both functional and decorative purposes. Aluminum coil distributors often supply customized rolls tailored to specific vehicle designs.

Home Appliance Manufacturing

In home appliances, orange peel embossed aluminum coil is favored for outer casings and internal components of refrigerators, washing machines, and microwaves. Its corrosion resistance and decorative finish meet consumer expectations for durability and style. The textured surface hides minor scratches, maintaining a clean look over time. Aluminum coil anodizing corp processes can further enhance surface hardness and color options, improving product lifespan and appeal.

Industrial and Machinery Uses

Industrially, this embossed aluminum coil is used for equipment casings, machine guards, and workbench surfaces where anti-slip and wear resistance are essential. Its lightweight yet strong nature facilitates easier handling and installation. The embossed texture also helps reduce light reflection and glare in work environments. Custom thickness and coating options from aluminum coil suppliers allow adaptation to various machinery requirements, improving safety and functionality.

Tip: When selecting orange peel embossed aluminum coil for your industry, consider the specific environmental conditions and required surface treatments to maximize durability and performance.

![2 2]()

Manufacturing Process of Orange Peel Embossed Aluminum Coil

The manufacturing of orange peel embossed aluminum coil involves several precise steps to ensure the final product meets performance and aesthetic standards. This process integrates material selection, embossing techniques, surface treatments, and rigorous quality control, making it suitable for diverse aluminium coil applications.

Material Selection and Preparation

Choosing the right aluminum alloy is the first crucial step. Common alloys include 1050, 1060, 3003, and 5052, each offering a balance of corrosion resistance, strength, and workability. Suppliers often provide aluminum coil rolls in various thicknesses ranging from 0.04 mm to 0.3 mm, tailored to specific needs. Before embossing, the coil undergoes cleaning and surface preparation to remove impurities, ensuring optimal adhesion of coatings and uniform embossing.

Embossing Techniques

The orange peel texture is created by passing the aluminum coil through embossing rollers engraved with the desired pattern. This cold rolling embossing process imprints the irregular, dimpled pattern resembling an orange peel. The embossing depth typically ranges between 0.08 mm and 0.25 mm, which enhances anti-slip properties and surface hardness. Advanced embossing equipment allows precise control over pattern consistency and depth, ensuring uniformity across the aluminum coil sheet or roll.

Surface Treatments

Post-embossing, the aluminum coil can undergo various surface treatments to boost durability and appearance. Common treatments include:

Anodizing: This electrochemical process forms a protective oxide layer, enhancing corrosion resistance and surface hardness. It also allows color customization while preserving the embossed texture.

Coating: Painted or coated aluminum coils receive polyester, fluorocarbon (PVDF), or high-durability polyester finishes. These coatings improve weather resistance and add decorative colors.

Oil Protection: A thin oil layer may be applied to prevent oxidation during storage and transport.

These treatments not only protect the coil but also expand its applications in environments requiring robust performance.

Quality Control Measures

Quality control is integral throughout the manufacturing process. Inspections focus on:

Dimensional Accuracy: Thickness, width, and coil weight are checked against specifications.

Embossing Consistency: Pattern depth and uniformity are measured to ensure anti-slip effectiveness and aesthetic appeal.

Surface Integrity: Coatings and anodized layers are tested for adhesion, corrosion resistance, and finish quality.

Mechanical Properties: Tensile strength and hardness tests confirm the coil can withstand application demands.

Reputable aluminum coil suppliers maintain strict quality standards to deliver products that meet industry and customer requirements.

Tip: When sourcing orange peel embossed aluminum coil, verify the manufacturer’s embossing precision and surface treatment capabilities to ensure the product matches your application’s durability and aesthetic needs.

Comparing Orange Peel Embossed Aluminum Coil with Other Patterns

When choosing an aluminum coil for your project, understanding how the orange peel embossed aluminum coil compares to other popular patterns is crucial. Let's explore the differences between the orange peel and diamond patterns, their performance characteristics, and visual appeal to help you make an informed decision.

Orange Peel vs Diamond Pattern

Texture and AppearanceThe orange peel embossed aluminum coil features an irregular, dimpled surface resembling the skin of an orange. This pattern provides a subtle, matte finish that reduces glare. In contrast, the diamond pattern shows a regular, geometric design with raised diamond shapes, creating a more pronounced 3D effect and a glossy look.

Anti-Slip PropertiesBoth patterns enhance slip resistance, but the orange peel texture offers a more diffused grip due to its finer, uneven surface. The diamond pattern provides sharper edges, which can offer stronger traction in heavy-duty flooring or industrial applications.

Strength and RigidityThe diamond embossed aluminum coil typically offers higher surface strength and rigidity because of its structured pattern, making it suitable for applications requiring extra durability. The orange peel pattern improves hardness but focuses more on aesthetics and moderate anti-slip functionality.

Performance Differences

| Feature | Orange Peel Embossed Aluminum Coil | Diamond Pattern Embossed Aluminum Coil |

| Surface Roughness | Moderate, uneven texture | Higher, sharp geometric texture |

| Anti-Slip Effect | Good for light to moderate use | Excellent for heavy-duty applications |

| Corrosion Resistance | Enhanced with coatings/anodizing | Similarly enhanced |

| Wear Resistance | Good | Superior due to pattern structure |

| Thermal Conductivity | Slightly improved by texture | Comparable, pattern impact minimal |

| Weight Impact | Minimal | Minimal |

Visual Appeal and Design Flexibility

Orange Peel TextureThis pattern lends a natural, understated look that works well in architectural applications, home appliance manufacturing, and decorative panels. It pairs beautifully with painted aluminum coil finishes, offering a wide range of colors and subtle texture that hides fingerprints and scratches.

Diamond PatternThe diamond embossed aluminum coil stands out with its bold, industrial aesthetic. It's often chosen for flooring, vehicle interiors, and packaging where a strong visual statement and enhanced durability are needed. The regular pattern allows for consistent reflections and a shiny finish when coated or anodized.

Both patterns can be customized in thickness, size, and surface coatings by aluminum coil suppliers to meet specific project requirements. Coated aluminum coils and anodized finishes further expand design options and functional benefits.

Tip: When selecting between orange peel and diamond embossed aluminum coils, consider your application’s slip resistance needs and desired visual style to balance safety, durability, and aesthetics effectively.

Customization Options for Orange Peel Embossed Aluminum Coil

Customizing orange peel embossed aluminum coil allows you to tailor the material to your project's specific needs. Aluminum coil suppliers offer a variety of options in color, size, thickness, and surface treatments to ensure optimal performance and aesthetics.

Color and Finish Variations

Orange peel embossed aluminum coil comes in a broad spectrum of colors and finishes. Painted aluminum coil options include matte, glossy, and satin finishes, providing flexibility for architectural or decorative uses. Coated aluminum coil variants use durable polyester or PVDF coatings, enhancing weather resistance and color longevity. Anodizing treatments from aluminum coil anodizing corp add metallic hues and increase corrosion resistance while preserving the textured surface.

Popular colors range from metallic silver, gold, bronze, and copper to vibrant blues, reds, and greens. This range supports diverse design schemes, whether for aluminum coil siding or appliance panels. The embossed texture also helps hide fingerprints and minor scratches, maintaining a clean appearance over time.

Thickness and Size Customization

Thickness customization is crucial for balancing strength and weight. Orange peel embossed aluminum coils typically range from 0.04 mm to 0.3 mm in thickness. Thinner gauges are suitable for lightweight applications like insulation or decorative panels, while thicker coils provide enhanced durability for structural uses.

Width and coil length are also adjustable. Standard widths vary from 200 mm to 1500 mm, with coil weights between 100 kg and 500 kg. Aluminum coil distributors can cut coils into sheets or rolls tailored to your project's dimensions. This flexibility ensures efficient material use and reduces waste.

Surface Coatings and Treatments

Surface treatments enhance the coil’s functional properties. Besides anodizing and painting, options include:

Oil Protection: A light oil layer prevents oxidation during storage and transport.

Polymer Coatings: Specialized anti-corrosion coatings improve resistance in harsh environments, ideal for outdoor applications.

Mirror Finishes: Polished embossed aluminum coil offers a reflective surface combined with texture, perfect for decorative or lighting applications.

These treatments extend the service life of aluminum coil products and adapt them to specific environmental conditions.

Tip: When ordering orange peel embossed aluminum coil, discuss your project's environmental exposure and design goals with your aluminum coil suppliers to select the best combination of color, thickness, and surface treatment.

Conclusion

Orange peel embossed aluminum coil offers enhanced anti-slip properties, improved corrosion resistance, and a decorative appeal. Its lightweight and durable nature make it ideal for various applications, from construction to automotive. Future prospects include innovations in surface treatments and customization options, ensuring the product meets diverse industry needs. When choosing the right aluminum coil, consider factors like thickness, color, and surface treatment to match specific requirements. Yuqi Metal provides high-quality orange peel embossed aluminum coils tailored to deliver exceptional value and performance.

FAQ

Q: What are the benefits of using orange peel embossed aluminum coil in construction?

A: Orange peel embossed aluminum coil offers enhanced anti-slip properties, improved corrosion resistance, and decorative appeal, making it ideal for aluminum coil siding, flooring, and wall cladding applications.

Q: How does the orange peel texture improve the performance of aluminum coil in refrigeration systems?

A: The orange peel texture increases surface area, enhancing thermal conductivity and heat dissipation. This benefits refrigeration equipment by boosting energy efficiency and extending the lifespan of components.

Q: Can orange peel embossed aluminum coil be customized for specific applications?

A: Yes, aluminum coil suppliers offer customization in color, thickness, and surface treatments, such as anodizing and coating, to meet specific project requirements and enhance durability.

Q: How does the price of orange peel embossed aluminum coil compare to other types?

A: The price of orange peel embossed aluminum coil can vary based on thickness, coatings, and supplier. It is generally competitive with other embossed patterns, offering unique benefits that justify its cost.

Q: Why is orange peel embossed aluminum coil preferred in automotive manufacturing?

A: Its anti-slip properties, lightweight nature, and scratch resistance make it ideal for vehicle interiors, flooring, and engine heat shields, enhancing safety and fuel efficiency.