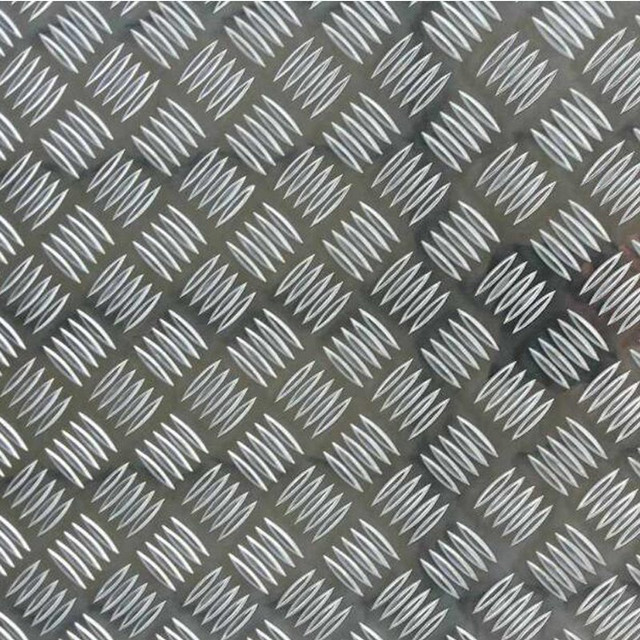

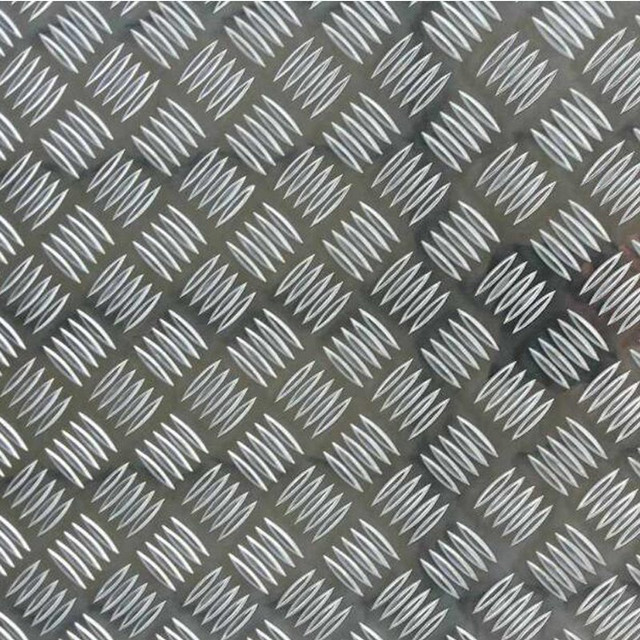

Imagine walking across a surface that offers safety without compromising on durability or aesthetics. That's the promise of Aluminum Tread Plate coil. Known for its embossed patterns, aluminum tread plate combines strength with slip resistance, making it essential for flooring and walkways. In this post, you'll learn about its characteristics, importance, and how it ensures safety in various applications.

Benefits of Using Tread Plate Aluminum Coil

Tread plate aluminum coil offers several advantages that make it a popular choice in flooring and walkway applications. Its unique combination of durability, corrosion resistance, and lightweight nature sets it apart from other materials.

Durability and Strength

Aluminum tread plate sheets provide excellent durability. The embossed patterns, such as diamond tread sheets or five-bar designs, add structural strength without significantly increasing weight. This makes aluminum floor plates and aluminum deck plates capable of withstanding heavy foot traffic, machinery, and other loads. For example, aluminum diamond plate for trailer floors resists dents and deformation, ensuring long-lasting performance. The strength-to-weight ratio of aluminum tread plates is favorable, offering robust protection while maintaining ease of handling.

Corrosion Resistance

One of the standout benefits of aluminum tread plate coils is their resistance to corrosion. Unlike steel tread plates that may rust over time, aluminum naturally forms a protective oxide layer. This makes aluminum tread plates ideal for environments exposed to moisture or chemicals, such as outdoor walkways or refrigerated truck floors. Aluminum diamond plate stair treads maintain their appearance and slip resistance even in humid or wet conditions. This corrosion resistance reduces maintenance costs and extends the lifespan of the flooring.

Lightweight Nature

Compared to steel or stainless steel alternatives, aluminum tread plates are significantly lighter. This lightweight nature simplifies installation and reduces transportation costs. Aluminum tread brite sheets, for instance, offer the same safety benefits as heavier materials but are easier to cut, shape, and install. The reduced weight also lessens structural load on supporting frameworks, which is crucial in applications like trailer floors or elevated walkways.

Tip: When selecting aluminum tread plate suppliers, prioritize those offering a range of thicknesses and patterns to match your project's durability and slip resistance requirements effectively.

Slip Resistance of Tread Plate Aluminum Coil

How Slip Resistance is Achieved

Aluminum tread plate coils achieve slip resistance primarily through their embossed surface patterns. These raised designs—such as diamond tread sheets, five-bar patterns, and lentil or orange peel textures—create friction points that improve grip underfoot. The protrusions interrupt smooth surfaces, reducing the risk of slips, especially in wet or oily conditions. For example, aluminum diamond plate for trailer floors uses these embossed patterns to provide traction that keeps cargo handlers safe.

The material’s texture works by increasing the coefficient of friction between the tread plate surface and footwear or equipment tires. This is crucial for aluminum floor plates and aluminum deck plates installed in high-traffic walkways or ramps. The slip-resistant quality is enhanced by the depth, shape, and spacing of the embossing, which varies depending on the pattern type chosen.

Comparison with Other Materials

Compared to other materials like steel or stainless steel tread plates, aluminum tread plates offer a balanced combination of slip resistance and lightweight convenience. Steel tread plates may provide higher load-bearing capacity but often lack the natural corrosion resistance of aluminum. This can lead to slippery surfaces when rust or grime accumulates. Stainless steel offers corrosion resistance but at a higher cost and weight.

Aluminum tread brite sheets, with their bright finish, not only improve aesthetics but also maintain slip resistance even after prolonged use. Unlike some rubber or plastic anti-slip solutions, aluminum tread plates do not degrade easily under heavy mechanical stress or extreme weather conditions, making them ideal for outdoor walkways and industrial flooring.

Importance in Safety Applications

Slip resistance is vital in environments where safety is paramount. Aluminum tread plates are widely used in stair treads, ramps, walkways, and trailer floors to prevent accidents caused by slips and falls. For instance, aluminum diamond plate stair treads provide secure footing in both commercial and industrial settings. In transportation, aluminum diamond plate for trailers enhances safety during loading and unloading.

The use of slip-resistant aluminum tread plate sheets helps companies comply with workplace safety regulations and reduces liability risks. It also improves worker confidence and productivity by providing stable footing in challenging conditions.

Testing and Standards for Slip Resistance

Slip resistance of aluminum tread plates is typically evaluated according to industry standards such as ASTM and OSHA guidelines. Tests measure the coefficient of friction under dry and wet conditions to ensure the material meets safety thresholds. Reliable aluminum tread plate suppliers often provide certification or test results demonstrating compliance.

Regular inspection and maintenance also play a role in preserving slip resistance. Dirt, oil, and wear can diminish the effectiveness of embossed patterns, so cleaning aluminum tread plates is essential to maintaining their safety benefits.

Tip: When selecting aluminum tread plate sheets for flooring or walkways, consider the pattern type and embossing depth to match the specific slip resistance requirements of your environment for optimal safety and performance.

Applications in Flooring and Walkways

Common Use Cases

Aluminum tread plate sheets are widely used in flooring and walkways due to their excellent slip resistance and durability. One of the most common applications is in trailer floors, where aluminum diamond plate for trailer floor provides a lightweight yet sturdy surface that withstands heavy loads and harsh conditions. Similarly, aluminum diamond plate for trailers is favored in the transportation industry for its corrosion resistance and anti-slip properties.

In industrial and commercial settings, aluminum floor plates and aluminum deck plates are often installed in walkways, ramps, and stair treads to enhance safety and durability. For example, aluminum diamond plate stair treads are popular in factories and public buildings, offering secure footing and reducing slip hazards. Outdoor walkways also benefit from aluminum tread brite sheets, which combine aesthetic appeal with functional slip resistance.

Advantages Over Other Materials

Compared to steel or stainless steel tread plates, aluminum tread plates offer several advantages. Their lightweight nature reduces structural load and simplifies installation, especially in elevated walkways or trailer floors. Unlike steel, aluminum tread plates resist rust and corrosion naturally, maintaining their appearance and slip resistance over time without frequent maintenance.

The embossed tread plate patterns, such as diamond tread sheets or five-bar designs, provide superior grip without compromising the material’s strength. This makes aluminum tread sheets ideal for environments exposed to moisture, oil, or chemicals, where slip resistance is critical. Additionally, aluminum’s recyclability aligns with sustainable building practices.

Installation Considerations

When installing aluminum tread plates for flooring or walkways, it is important to consider the thickness and pattern type to match the specific load and slip resistance requirements. For heavy-duty uses like trailer floors, thicker plates such as 1/8 aluminum tread plate or more robust aluminum deck plates are recommended. For pedestrian walkways and stair treads, patterns like diamond or five-bar provide optimal traction.

Proper surface preparation and fastening methods ensure the tread plate remains securely in place under heavy traffic. It is also essential to source aluminum tread plate sheets from reputable aluminum tread plate suppliers to guarantee material quality and compliance with safety standards.

Tip: When planning flooring or walkway projects, choose aluminum tread plate sheets with appropriate thickness and embossed patterns to balance slip resistance and durability for your specific application.

![embossed15 embossed15]()

Types and Patterns of Tread Plate Aluminum

When selecting an aluminum tread plate sheet for flooring or walkways, understanding the available types and patterns is essential. The pattern not only affects the aesthetic appeal but also influences slip resistance and durability.

Common Patterns Available

Aluminum tread plates come in various embossed patterns designed to enhance grip and structural strength. The most common include:

Diamond Tread Sheet: Features raised diamond shapes that provide excellent slip resistance, widely used in trailer floors and industrial walkways.

Five-Bar Pattern: Also known as the willow leaf pattern, it consists of parallel bars arranged in a staggered layout, offering strong anti-slip properties and load-bearing capacity.

Three-Bar and Two-Bar Patterns: Simpler designs used where moderate traction is sufficient.

Orange Peel Embossed Plate: Displays a subtle textured surface resembling an orange peel, often used for decorative purposes with some slip resistance.

Lentil or Dutch Pea Pattern: Circular raised bumps that enhance grip, common in vehicle floors and ramps.

Spherical or Pearl Pattern: Small hemispherical bumps that increase surface friction and add an attractive finish.

These patterns vary in size and height of embossing, directly impacting performance. For example, larger diamond or five-bar patterns typically offer better traction but may be less comfortable underfoot for pedestrian walkways.

Choosing the Right Pattern for Your Needs

Selecting the correct pattern depends on the application:

For heavy-duty flooring like aluminum diamond plate for trailer floors, the diamond or five-bar patterns excel due to their robust anti-slip qualities and ability to withstand mechanical stress.

In pedestrian walkways and stair treads, aluminum diamond plate stair treads with smaller, closely spaced patterns provide safer footing without excessive protrusion.

For decorative or light-duty uses, aluminum tread brite sheets with bright finishes and subtle embossing balance aesthetics and functionality.

When corrosion resistance is critical, such as in marine environments, pairing the right alloy (e.g., 3003 or 5052 aluminum tread plates) with an appropriate pattern ensures longevity.

Thickness also plays a role; for example, a 1/8 aluminum tread plate thickness is common for flooring applications that require durability without excessive weight.

Impact of Pattern on Performance

The embossed pattern influences several key performance aspects:

Slip Resistance: Raised patterns increase friction, reducing slip risks. Patterns with sharp edges like diamond tread plates offer superior grip, especially in wet or oily conditions.

Load Distribution: Patterns add rigidity and help distribute weight evenly, enhancing the structural strength of aluminum floor plates and deck plates.

Wear and Maintenance: Some patterns trap dirt or debris, potentially reducing slip resistance over time. Choosing patterns that are easier to clean, like five-bar or diamond plate, helps maintain safety.

Aesthetic Appeal: Patterns contribute to the visual design, important in architectural or decorative applications.

Tip: When sourcing aluminum tread plate sheets, consult with aluminum tread plate suppliers about pattern options tailored to your specific flooring or walkway needs to optimize slip resistance and durability.

Comparing Tread Plate Aluminum to Other Materials

When choosing materials for flooring and walkways, understanding how aluminum tread plate compares to steel and stainless steel is crucial. Each has its strengths, but aluminum tread plate offers a unique balance of properties that often make it the preferred choice for many applications.

Tread Plate Aluminum vs. Steel

Steel tread plates are known for their exceptional strength and durability. They can handle heavy loads and impacts, making them suitable for industrial environments with intense wear and tear. However, steel is significantly heavier than aluminum tread plates, which can complicate installation and increase transportation costs.

Another consideration is corrosion resistance. Steel tends to rust when exposed to moisture unless it is coated or galvanized. Over time, rust can degrade the surface, reducing slip resistance and increasing maintenance needs. In contrast, aluminum tread plates naturally resist corrosion due to their oxide layer, making them ideal for outdoor walkways, ramps, and trailer floors where moisture exposure is common.

Additionally, aluminum tread plates remain cooler to the touch in hot environments and are easier to cut and shape during installation. This lightweight nature reduces structural load, which is beneficial in applications like aluminum diamond plate for trailer floors or aluminum deck plates on elevated platforms.

Tread Plate Aluminum vs. Stainless Steel

Stainless steel tread plates combine strength with corrosion resistance. They excel in environments requiring hygiene and durability, such as food processing plants and chemical facilities. Stainless steel is harder and more impact-resistant than aluminum, but it comes with a higher cost and greater weight.

Aluminum tread plates, while not as strong as stainless steel, provide sufficient strength for most flooring and walkway uses. They are easier to work with and more cost-effective, especially when corrosion resistance and slip resistance are priorities without the need for extreme load-bearing capacity.

The bright finish of aluminum tread brite sheets also offers aesthetic advantages over the often duller stainless steel surfaces. For example, aluminum diamond plate stair treads are popular in commercial settings where appearance matters alongside safety.

Cost-Effectiveness and Long-Term Benefits

From a cost perspective, aluminum tread plates generally offer better value. They are less expensive than stainless steel and reduce labor costs due to easier handling and installation. Their corrosion resistance minimizes maintenance expenses and extends service life, especially in outdoor or humid environments.

Steel may require protective coatings and more frequent upkeep, adding to overall costs. Stainless steel, while durable, has a higher upfront price that may not be justified for all applications.

In summary, aluminum tread plates provide a compelling mix of durability, corrosion resistance, slip resistance, and lightweight convenience. This makes them an excellent choice for a broad range of flooring and walkway projects, including aluminum diamond plate for trailers and aluminum floor plates in industrial settings.

Tip: When evaluating materials for flooring or walkway projects, consider aluminum tread plates for their balance of slip resistance, corrosion resistance, and ease of installation to optimize long-term performance and cost-efficiency.

Maintenance and Care for Tread Plate Aluminum Flooring

Proper maintenance and care of aluminum tread plate flooring ensure long-lasting performance, safety, and appearance. Whether you have aluminum diamond plate for trailer floors or aluminum deck plates in walkways, following best practices in cleaning, repair, and upkeep is essential.

Cleaning and Upkeep

Regular cleaning prevents dirt, oil, and debris buildup that can reduce slip resistance. Use mild detergents and water with a soft brush or mop to clean aluminum tread plate sheets. Avoid harsh chemicals or abrasive cleaners that may damage the embossed tread pattern or finish, such as aluminum tread brite surfaces.

For stubborn stains or grease, a diluted solution of vinegar or a non-abrasive degreaser works well. Rinse thoroughly with clean water to remove residues. Drying the surface after cleaning helps prevent water spots and maintains traction.

Routine inspections are important to check for wear or damage. Keeping the surface free of contaminants maintains the effectiveness of the slip-resistant embossed tread plate.

Repair and Replacement Tips

Minor dents or scratches in aluminum tread plates can often be smoothed out using light sanding or polishing, especially on aluminum diamond plate stair treads or floor plates. For damaged sections that compromise safety or structural integrity, replacement is recommended.

When replacing aluminum tread sheets, ensure the new material matches the existing pattern and thickness, such as 1/8 aluminum tread plate, to maintain uniform slip resistance and load capacity. Professional installation helps secure the plates correctly and prevents loosening under foot traffic or mechanical loads.

For trailer floors or outdoor walkways, consider protective coatings or anodizing to extend lifespan and ease cleaning. However, coatings should not reduce the anti-slip properties of the embossed tread.

Longevity and Durability

Aluminum tread plates are inherently durable and corrosion-resistant, especially alloys like 3003 or 5052. Proper maintenance enhances these qualities, allowing the flooring or walkway to last for many years.

Avoid exposing aluminum tread plates to extreme chemicals or abrasive wear beyond their design limits. In industrial settings, scheduled maintenance and prompt repairs reduce the risk of accidents and costly replacements.

Using aluminum tread plate sheets from reputable aluminum tread plate suppliers ensures consistent quality and performance. Quality materials combined with good care practices maximize the benefits of aluminum tread flooring.

Tip: Schedule regular cleaning and inspections of aluminum tread plate flooring to preserve slip resistance and extend service life, especially in high-traffic or outdoor environments.

Conclusion

Tread plate aluminum coil offers durability, corrosion resistance, and lightweight convenience, making it ideal for flooring and walkways. Its slip-resistant patterns enhance safety in high-traffic areas. Compared to steel, it provides superior corrosion resistance, while being more cost-effective than stainless steel. Proper maintenance ensures long-lasting performance. As industries seek sustainable solutions, innovations in aluminum tread plates continue to evolve. For quality products, consider Yuqi Metal, which delivers exceptional value with its range of aluminum tread plate options.

FAQ

Q: What makes Aluminum Tread Plate ideal for flooring and walkways?

A: Aluminum Tread Plate is ideal for flooring and walkways due to its slip resistance, lightweight nature, and corrosion resistance. The embossed patterns, such as diamond tread sheets, provide excellent grip, making it a safe choice for high-traffic areas.

Q: How does an Aluminum Diamond Plate for trailer floors enhance safety?

A: An Aluminum Diamond Plate for trailer floors enhances safety by providing a slip-resistant surface through its raised patterns, reducing the risk of slips and falls during loading and unloading.

Q: Why choose Aluminum Tread Plate over steel for walkways?

A: Aluminum Tread Plate is preferred over steel for walkways due to its lightweight nature, corrosion resistance, and ease of installation, offering long-term durability with minimal maintenance.

Q: What are the benefits of using Aluminum Tread Brite sheets in outdoor walkways?

A: Aluminum Tread Brite sheets offer both aesthetic appeal and functional slip resistance, making them ideal for outdoor walkways where appearance and safety are important.

Q: Where can I find reliable Aluminum Tread Plate suppliers?

A: Reliable Aluminum Tread Plate suppliers can be found by researching companies that offer a variety of thicknesses and patterns, ensuring they meet specific project requirements for durability and slip resistance.