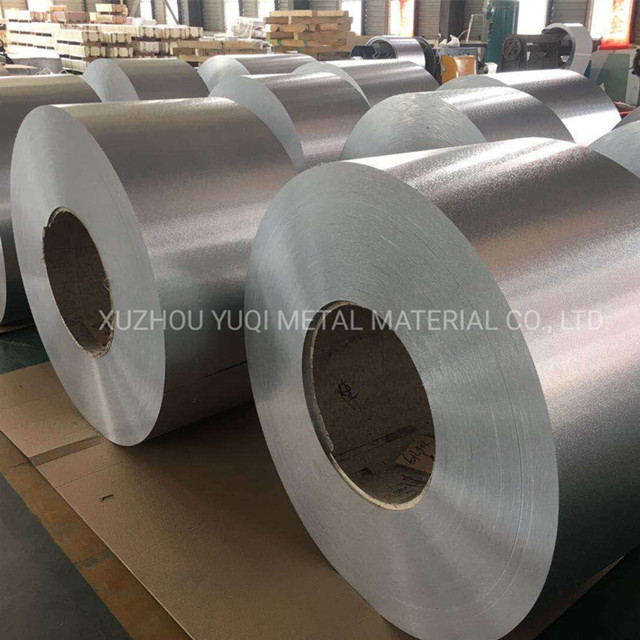

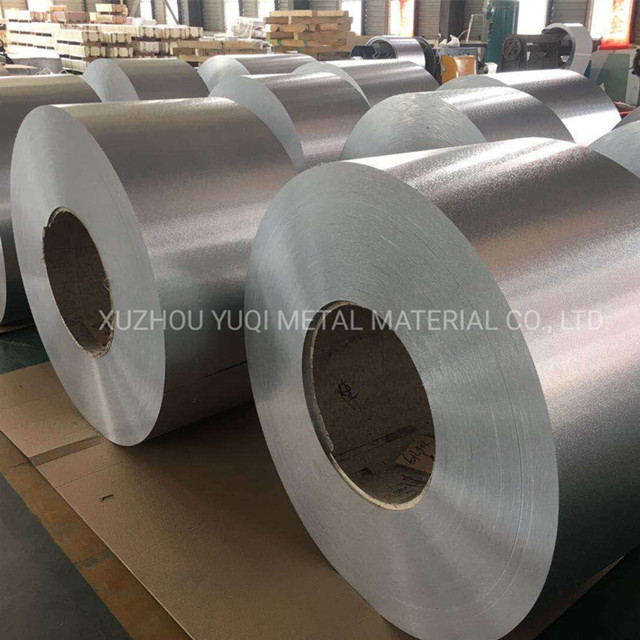

Have you ever wondered what gives certain aluminum surfaces their unique texture and durability? Stucco embossed aluminum coil might be the answer. This material combines aesthetic appeal with practical benefits, making it a favorite in various industries. In this post, you'll learn what stucco embossed aluminum coil is, the embossing process, and its key characteristics. Discover how this versatile material can enhance your projects.

Benefits of Stucco Embossed Aluminum Coil

Stucco embossed aluminum coil offers several advantages that make it a preferred choice in various industries. Its unique combination of durability, aesthetic appeal, lightweight nature, and corrosion resistance sets it apart from other aluminum coil products.

Durability and Strength

One of the main benefits of stucco embossed aluminum coil is its enhanced durability. The embossing process adds texture and thickness to the aluminum coil sheet, increasing its overall strength. This makes it highly resistant to dents and scratches compared to mill finish aluminum coil. The raised stucco pattern also helps to hide minor surface imperfections, extending the material's lifespan. These qualities make it ideal for demanding applications such as aluminum coil siding and aluminum coil fascia, where structural integrity is crucial.

Aesthetic Appeal

The stucco embossed pattern provides a distinctive, textured surface that enhances the visual appeal of aluminum coil products. This finish mimics the classic stucco look but with the benefits of aluminum, making it suitable for architectural decoration and interior design. Whether used in aluminum coil siding or decorative panels, the embossed texture adds depth and character to surfaces. It also offers versatility in design, accommodating various styles from modern to traditional. This aesthetic advantage often influences buyers searching for aluminum coil for sale, as it combines beauty with functionality.

Lightweight and Easy to Install

Aluminum coil, including stucco embossed varieties, is known for being lightweight. This characteristic simplifies handling, transportation, and installation, reducing labor costs and time on-site. The lightweight nature does not compromise strength, making it a practical choice for applications like aluminum coil fascia and cladding. Additionally, the material’s flexibility allows it to be bent and shaped without cracking, which is beneficial in construction and manufacturing processes.

Corrosion Resistance

Aluminum naturally resists corrosion, and the stucco embossed finish further enhances this property by creating a protective barrier against environmental factors. This makes stucco embossed aluminum coil suitable for outdoor applications where exposure to moisture and weather is common. The embossed texture also helps to reduce surface wear and tear, contributing to the long-term preservation of the material. Many aluminum coil distributors and stucco embossed aluminum coil suppliers emphasize this feature when promoting their products, as it ensures durability in harsh conditions.

Tip: When selecting stucco embossed aluminum coil, consider suppliers who offer anodized or coated finishes to maximize corrosion resistance and extend product lifespan in outdoor environments.

![c c]()

Applications of Stucco Embossed Aluminum Coil

Stucco embossed aluminum coil stands out not just for its durability and aesthetic appeal but also for its versatility across various industries. Its unique textured surface and functional benefits make it a valuable material in multiple applications.

Use in Architectural Decoration

In architecture, stucco embossed aluminum coil is widely favored for both exterior and interior decoration. It is commonly used in aluminum coil siding and aluminum coil fascia, where it enhances building facades with a distinctive textured finish. The stucco pattern adds depth and character, creating a sophisticated look that mimics traditional stucco but with the advantages of aluminum’s lightweight and corrosion resistance. This makes it ideal for curtain walls, decorative cladding, and interior feature walls. The material’s ease of installation and maintenance further supports its popularity among aluminium sheet coil suppliers and aluminum coil distributors catering to construction projects.

Role in Transportation Industry

The transportation sector benefits significantly from stucco embossed aluminum coil. Its lightweight nature contributes to fuel efficiency in vehicles by reducing overall weight without sacrificing strength. The embossed texture also improves grip and reduces slipping, which is crucial in applications like truck bed liners and trailer flooring. Additionally, the corrosion resistance of aluminum coil anodizing corp products ensures longevity despite exposure to harsh weather and road conditions. This material finds use in automotive trim panels, ship interiors, and even railway car components, where durability and aesthetics are equally important.

Importance in Electronics and Appliances

In electronics and household appliances, the stucco embossed aluminum coil is prized for its excellent thermal conductivity and electromagnetic shielding properties. The embossed surface increases surface area, enhancing heat dissipation in components such as radiators and appliance casings. This pattern is often seen in refrigerator panels, air conditioning units, and other appliances where both function and appearance matter. Aluminium coil sheet manufacturers supply these coils to appliance makers who seek materials that combine durability with an attractive finish.

Industrial Applications

Industrially, stucco embossed aluminum coil is used in a range of applications requiring strength and anti-slip properties. Flooring, ramps, and steps often utilize embossed aluminum coil sheets with stucco patterns to improve safety. Toolboxes, machinery housings, and ventilation ducts also benefit from the added thickness and resistance the embossing provides. The material’s corrosion resistance and ease of cleaning make it suitable for environments with exposure to moisture or chemicals. Aluminium coil roll suppliers often stock these coils to meet diverse industrial demands.

Tip: When sourcing stucco embossed aluminum coil, consider suppliers who offer a range of alloy grades and embossing patterns to best meet your project's specific functional and aesthetic requirements.

Manufacturing Process of Stucco Embossed Aluminum Coil

The manufacturing of stucco embossed aluminum coil involves several precise steps, ensuring the final product meets both aesthetic and functional standards. This process transforms standard aluminum coil into a textured, durable material ideal for various industrial and architectural uses.

Material Preparation and Cleaning

The process begins with selecting high-quality aluminum coil, often from alloys such as 1060, 3003, or 5052, chosen for their excellent formability and corrosion resistance. Before embossing, the aluminum coil sheet undergoes thorough cleaning and degreasing. This step removes oils, dirt, and other contaminants that could interfere with embossing or finishing. Clean surfaces ensure uniform embossing and better adhesion for subsequent coatings or anodizing treatments.

Embossing Techniques

Embossing is the core step where the stucco pattern is applied. The cleaned aluminum coil passes through embossing rollers or presses equipped with patterned dies. These tools apply heat and mechanical pressure, imprinting the characteristic stucco texture onto the aluminum sheet coil surface. The embossing not only enhances the aluminum coil’s decorative appeal but also increases its thickness and strength. This pattern provides anti-slip properties and helps mask minor surface imperfections.

Different embossing patterns exist, but the stucco embossed aluminum coil is distinguished by its random, rough texture resembling traditional stucco plaster. This process requires precise control of temperature and pressure to ensure consistent pattern depth and clarity across the coil length.

Finishing and Surface Treatments

After embossing, the aluminum coil may undergo various surface treatments to enhance corrosion resistance and appearance. Common finishing methods include anodizing, painting, or applying protective coatings. For example, anodizing by an aluminum coil anodizing corp adds a durable oxide layer that improves weather resistance and extends lifespan, especially for outdoor applications like aluminum coil siding or fascia.

These finishing steps also allow stucco embossed aluminum coil suppliers to offer customized colors and gloss levels, meeting specific architectural or industrial requirements.

Quality Control and Inspection

Quality control is critical throughout the manufacturing process. After embossing and finishing, the aluminum coil undergoes rigorous inspection to verify pattern consistency, surface integrity, and coating adhesion. Any defects such as uneven embossing, scratches, or coating flaws are identified and corrected.

Testing may include visual inspections, thickness measurements, corrosion resistance assessments, and mechanical strength tests. Aluminium sheet coil suppliers emphasize quality to ensure customers receive reliable, high-performance products suitable for demanding applications.

Tip: When sourcing stucco embossed aluminum coil, request detailed information on the embossing process and finishing treatments to ensure the product matches your project’s durability and aesthetic requirements.

Comparing Stucco Embossed Aluminum Coil to Other Patterns

When choosing embossed aluminum coil, understanding the differences between popular patterns helps in selecting the right material for your project. Stucco embossed aluminum coil stands out due to its unique texture and functional benefits, but how does it compare to other common patterns like diamond and orange peel? Let’s explore these differences and the advantages of the stucco pattern.

Stucco vs. Diamond Pattern

The stucco pattern features a random, rough texture resembling traditional stucco plaster. It consists of small, uneven bumps that provide excellent anti-slip properties and help hide surface imperfections. This makes stucco embossed aluminum coil ideal for applications requiring grip and durability, such as flooring, ramps, and siding.

In contrast, the diamond pattern displays a uniform series of raised diamond shapes arranged in a regular grid. This pattern enhances structural rigidity and resistance to bending, making it popular in truck beds, toolboxes, and vehicle panels. While diamond embossing offers superior strength, it tends to be less effective at masking minor surface flaws compared to the stucco pattern.

| Feature | Stucco Pattern | Diamond Pattern |

| Texture | Random, rough, stucco-like bumps | Regular, raised diamond shapes |

| Anti-slip properties | Excellent | Good |

| Structural rigidity | Moderate | High |

| Surface imperfection coverage | Very effective | Less effective |

| Common applications | Siding, flooring, ramps | Vehicle beds, toolboxes |

Stucco vs. Orange Peel Pattern

The orange peel pattern resembles the surface of an orange peel, with small, rounded bumps evenly distributed. It offers good anti-slip properties and a decorative appearance, often used in refrigerator panels, air conditioning units, and decorative trims.

Compared to the orange peel, stucco embossing has a rougher, more random texture. Stucco excels in outdoor and industrial uses where grip and durability matter most. Orange peel, meanwhile, is favored for appliance surfaces and architectural elements where a smoother, more refined texture is desired.

Advantages of Stucco Pattern

Enhanced Grip: The irregular bumps provide superior anti-slip qualities, ideal for safety-critical surfaces.

Surface Concealment: It effectively hides scratches and dents, maintaining an attractive look over time.

Versatility: Suitable for both industrial and architectural applications, from aluminum coil siding to flooring.

Durability: Adds thickness and strength to the aluminum coil sheet, extending service life.

Aesthetic Appeal: Mimics traditional stucco finish, adding texture and depth to surfaces.

In summary, the stucco embossed aluminum coil offers a balanced combination of functionality and aesthetics. It is particularly well-suited for applications requiring slip resistance and surface durability, while still providing an attractive finish. When sourcing from stucco embossed aluminum coil suppliers or aluminum coil distributors, consider the specific pattern benefits to match your project needs.

Tip: For projects demanding both high strength and anti-slip properties, consider combining stucco embossed aluminum coil with complementary patterns like diamond embossing to optimize performance and appearance.

Maintenance and Care for Stucco Embossed Aluminum Coil

Proper maintenance of stucco embossed aluminum coil is essential to preserve its durability, appearance, and functional benefits. These coils, widely used in siding, fascia, and various industrial applications, require routine care to maintain their corrosion resistance and textured finish.

Routine Cleaning Techniques

Cleaning stucco embossed aluminum coil is straightforward due to its corrosion-resistant surface. For regular upkeep, simply dust off dirt and debris using a soft, dry cloth or a gentle brush. This prevents buildup that could dull the embossed texture.

For deeper cleaning, use a mild detergent mixed with warm water. Apply the solution with a soft sponge or cloth, gently wiping the surface. Avoid abrasive cleaners or rough scrubbing tools, as they can scratch or damage the embossed aluminum coil sheet. After cleaning, rinse thoroughly with clean water to remove any detergent residue, then dry the surface with a soft towel to prevent water spots.

Periodic Inspections

Regular inspections help identify early signs of wear, corrosion, or damage. Check the aluminum coil siding or fascia for scratches, dents, or coating degradation. Pay special attention to edges and joints where moisture can accumulate. Maintaining protective coatings, such as anodized layers or paint, is critical for long-term corrosion resistance.

If you notice any damaged areas, promptly repair or replace the affected sections to avoid further deterioration. Keeping in touch with stucco embossed aluminum coil suppliers for recommended maintenance products can also help preserve the material’s quality.

Handling and Storage Tips

Proper handling and storage reduce the risk of damage before installation or during maintenance. When moving aluminum coil rolls, use clean gloves to avoid fingerprints or oils that may affect surface coatings. Store coils in a dry, well-ventilated area away from direct sunlight and corrosive substances.

Avoid stacking coils directly on the floor or each other without protective padding. Use pallets or racks to keep them elevated and prevent moisture contact. During transport, secure the coils firmly to prevent shifting or impact damage.

Tip: Always use non-abrasive cleaning agents and soft cloths when maintaining stucco embossed aluminum coil to protect its textured finish and prolong its lifespan.

Conclusion

Stucco embossed aluminum coil offers durability, aesthetic appeal, lightweight installation, and corrosion resistance. Future trends show increasing use in architecture, transportation, electronics, and industry. Yuqi Metal provides high-quality stucco embossed aluminum coils with unique benefits, enhancing project value through superior materials and services.

FAQ

Q: What is a stucco embossed aluminum coil?

A: A stucco embossed aluminum coil is an aluminum coil sheet with a textured surface resembling traditional stucco plaster. This embossing enhances durability, aesthetic appeal, and slip resistance, making it ideal for various applications like aluminum coil siding and industrial flooring.

Q: Where is stucco embossed aluminum coil commonly used?

A: Stucco embossed aluminum coil is used in architectural decoration, transportation, electronics, and industrial applications. Its durability and aesthetic appeal make it suitable for aluminum coil fascia, siding, and decorative panels, as well as vehicle and appliance components.

Q: Why choose stucco embossed aluminum coil over other patterns?

A: Stucco embossed aluminum coil offers superior anti-slip properties, effective surface imperfection coverage, and a unique aesthetic. It is ideal for applications requiring durability and grip, such as aluminum coil siding, compared to other patterns like diamond or orange peel.

Q: How does the price of stucco embossed aluminum coil compare to other coils?

A: The aluminum coil price for stucco embossed varieties may vary based on factors like thickness, finish, and supplier. Generally, it offers good value due to its enhanced durability and aesthetic benefits, appealing to buyers looking for aluminum coil for sale.

Q: What maintenance does stucco embossed aluminum coil require?

A: Routine cleaning with mild detergent and water, regular inspections for damage, and proper storage are essential to maintain stucco embossed aluminum coil. These practices help preserve its corrosion resistance and textured finish, ensuring longevity in applications like aluminum coil siding.