Aluminum foil is an ultra-thin aluminum product, typically less than 0.2 mm in thickness. Made from high-purity aluminum (around 92% to 99% Al), it is flexible, lightweight, and subject to bending or tearing depending on treatment. Because of its excellent barrier, thermal, and chemical properties, aluminum foil is widely used in packaging, insulation, electronics, and other industries.

Classification of Aluminum Foil

By Surface Finish (Surface State)

Aluminum foil can be divided into one side of light aluminum foil and two sides of light aluminum foil. There are also plain / matte / textured / embossed / coated / composite types, depending on additional processing after rolling.

Single-side light aluminum foil:

In the rolling process (double rolling), one side of the foil contacts a polished roller (becoming shiny), while the other side is in contact with a dull roll or is unsupported (giving a darker or matte side). The bright side is the “light” side. Thickness of such foil often does not exceed 0.025 mm.

Double-sided light aluminum foil:

Produced via single-sheet rolling where both sides of the sheet contact rollers, giving both faces a metallic luster. Depending on roller roughness, it is further categorized into mirror double-sided and ordinary double-sided. Thickness generally is not less than 0.01 mm.

![foil7 foil7]()

Single-side light aluminum foil

![foil8 foil8]()

Double-sided light aluminum foil

By Thickness / Gauge

Aluminum foil can be divided into thick foil, single zero foil and double zero foil .

Thick foil (heavy gauge foil) :

Foil with thickness in the range 0.1 mm ~ 0.2 mm (or sometimes above typical light-foil ranges).

Single zero foil (medium gauge foil ):

Foil whose thickness is ≥ 0.01 mm but less than 0.1 mm.

Double zero foil (" light gauge foil ") :

Foil whose thickness is < 0.01 mm — typically in the range 0.005 mm ~ 0.009 mm. Some ultra-thin foils may be 0.0055 mm or even less.

Note: Some producers refer to thickness < 0.0055 mm as “ultra-thin foil”.

By Temper / Hardness State

Aluminum foil can be divided into hard foil, semi-hard foil and soft foil.

Hard foil:

After rolling without annealing (softening), foil retains hardness and sometimes residual rolling oil. Before printing, lamination, or coating, it usually must be degreased. It can be used as-is if the application involves forming.

Semi-hard foil:

A foil in between hard and soft in terms of strength and flexibility. Often used for forming operations.

Soft foil:

Fully annealed, flexible, with no residual oil, easy to process further. Common for packaging, composite materials, electrical foils, etc.

![Hydrophilic_副本 Hydrophilic_副本]()

| Classification Basis | Type / Category | Typical Thickness | Key Features / Notes |

| Surface Finish | Single-sided bright foil | ≤ 0.025 mm | One side polished (bright), the other side matte |

| Double-sided bright foil | ≥ 0.01 mm | Both sides polished—may be mirror finish or standard bright on both faces |

| Thickness / Gauge | Heavy gauge foil (Thick foil) | 0.10 – 0.20 mm | High strength, rigidity, used in appliances, HVAC, containers |

| Single zero foil (Medium gauge foil) | ≥ 0.01 mm and < 0.10 mm | Balance of flexibility and strength, many packaging/industrial uses |

| Double zero foil (Light gauge foil) | < 0.01 mm (e.g. 0.005 – 0.009 mm) | Very thin, highly flexible, often laminated for barrier performance |

| Temper / Hardness | Hard foil | As-rolled, not annealed | High strength but lower formability; may have residual oil—needs degreasing before printing/lamination |

| Semi-hard foil | Intermediate temper | Moderate strength & formability, used in forming/processing |

| Soft foil | Fully annealed | Very flexible, ideal for packaging, composites, electrical foils |

Enriched / Additional Notes & Best Practices

As thickness decreases, the challenges in rolling increase — defects like pinholes, inclusions, coarse grains become more pronounced. Controlling the quality of the aluminum blanks (ingots, casting, rolling) is critically important for achieving good yields in thin foil production.

In double-sided bright foils, the smoothness and finish of rollers influence surface quality and reflectivity.

Double-zero foils are regarded as high-end in many fields (e.g. packaging, electronics) because their manufacture is more demanding.

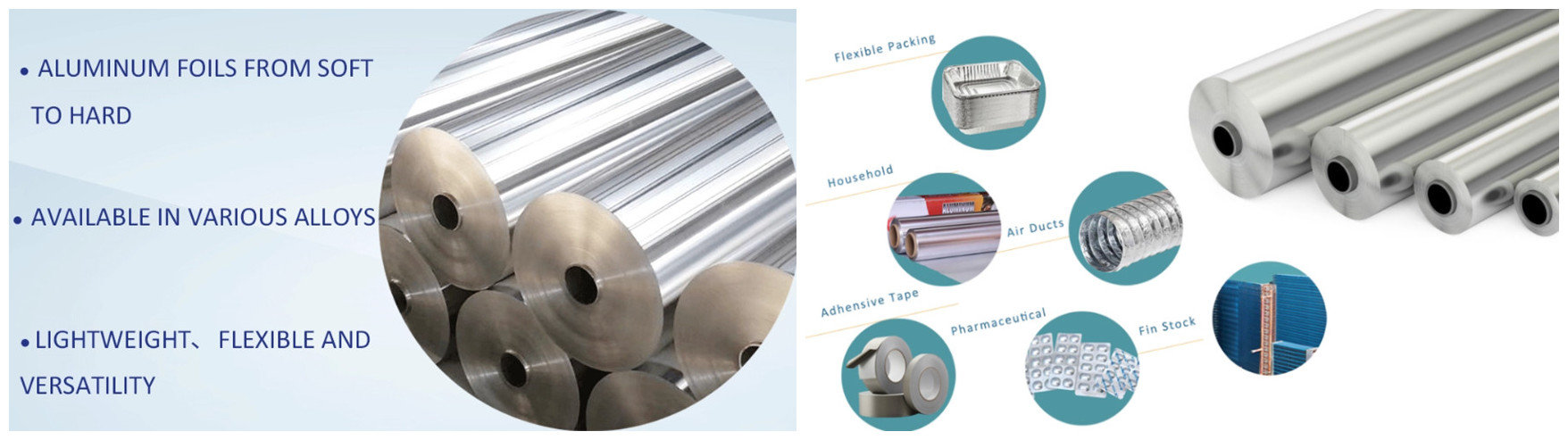

Applications of Aluminum Foil

| Application Area | Typical Usage / Role | Key Advantages / Features |

| Packaging & Food / Pharma | Lidding foil, blister packs, pouch wraps, tray seals | Excellent barrier to moisture, oxygen & light; food-safe; extends shelf life. |

| Construction & Insulation | Vapor barriers, radiant insulation layers, duct lining | Reflects ~96% of radiant heat; resists moisture; improves thermal insulation. |

| Electronics & Electrical | EMI / RFI shielding, capacitor foil, battery collector foil | High electrical conductivity; flexible foil for deep electronics use. |

| HVAC / Heat Exchangers | Fin foil, coated foil for AC / refrigeration systems | Improves heat transfer; can be hydrophilic, coated for corrosion resistance. |

| Industrial & Machinery | Protective wraps, thermal shields, barrier liners | Chemical resistance, flexibility, durability for industrial conditions. |

| Household / Kitchen Use | Food wrapping, oven lining, freezing / grilling wrap | Lightweight, non-toxic, flexible, easy to shape. |

| Decorative / Specialty | Laminated foil layers, decorative finishes, composite panels | Can be embossed, coated, printed; offers aesthetic + functional use. |

FAQ

Q1: What is “double zero” aluminum foil?

A: Double zero foil refers to foil with thickness less than 0.01 mm (often 0.005–0.009 mm). It's considered “light gauge” foil in industry.

Q2: How does single-sided bright foil differ from double-sided bright foil?

A: Single-sided bright foil has one polished (bright) side and one dull side; double-sided bright foil has both faces polished, often with better reflectivity.

Q3: What thickness ranges are typical for aluminum foil gauges?

A: Thick foil: ~0.1–0.2 mm. Single zero: ≥0.01 mm to <0.1 mm. Double zero: <0.01 mm (commonly 0.005–0.009 mm).

Q4: When should foil be degreased?

A: Hard foil, which has not been softened, often retains rolling oil and requires degreasing before printing, coating or lamination.

Q5: What applications use double zero foil?

A: Packaging (food, pharmaceuticals), electronics (foil layers, shielding), composite laminates, insulation.