Product Overview

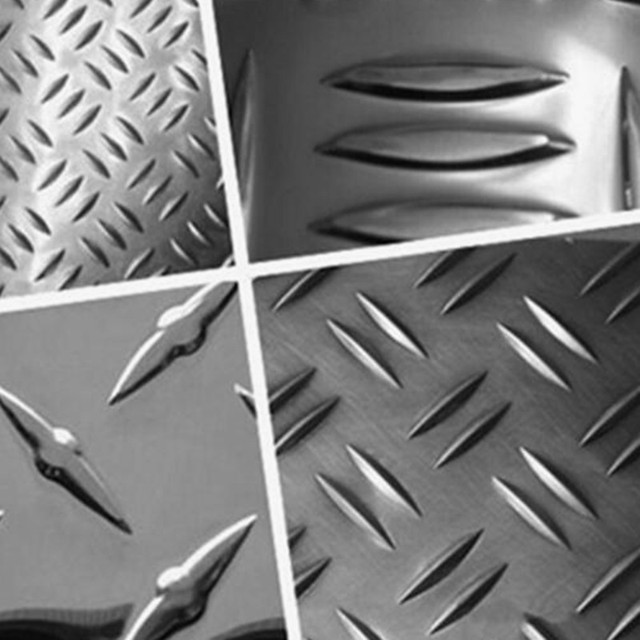

This Embossed Aluminum Coil / Sheet is designed for anti-slip stair flooring, industrial walkways, ramps, and architectural stair treads. Its raised checkered or tread patterns provide excellent traction, reducing slip risk while preserving aluminum’s lightweight, corrosion resistance, and ease of fabrication.

Available in coil or cut-sheet form, we support multiple alloys, thicknesses, emboss patterns (diamond, 5-bar, stucco, etc.), and custom widths for stair systems, platform surfaces, and safety flooring.

Key Features & Advantages

Superior Anti-Slip Performance — raised patterns (diamond, 5-bar, stucco) increase grip and safety.

Enhanced Rigidity — embossing work-hardens and stiffens thin sheets without adding weight.

Lightweight & Durable — aluminum core offers corrosion resistance and long service life.

Low Glare & Conceals Imperfections — textured surfaces diffuse light and hide scratches.

Versatile Alloy & Gauge Options — supports 1xxx / 3xxx / 5xxx series in various thicknesses.

Flexible Fabrication — coil or sheet format, easy cutting, bending, forming, installation.

Material & Specification Options

| Parameter | Range / Option | Note |

| Alloys | 1050, 1060, 3003, 5052, etc. | Choosing strength vs formability |

| Thickness | 0.5 mm – 4.0 mm (customizable) | For stair treads, flooring, ramp panels |

| Width / Coil Size | Up to 1600 mm+ | Can slit or cut per project |

| Embossed Patterns | Diamond, 5-Bar, Stucco, Orange Peel | Different anti-skid behavior |

| Surface Finish | Mill, anodized, coated, painted | Based on environment / aesthetics |

| Temper | O, H14, H24, etc. | For forming or rigidity balancing |

| Tolerances | Width ±0.2 mm, Thickness ±0.05 mm | Ensures consistency for panel fits |

![a3 a3]()

✅ Application Scenarios & Use Cases of Embossed / Checkered Aluminum Plate

The Embossed / Checkered Aluminum Coil and Sheet is a highly versatile anti-slip material used across multiple industries, combining lightweight strength, corrosion resistance, and excellent traction performance.

Below are the most common and high-value application scenarios, carefully categorized for SEO relevance and buyer intent.

Industrial Flooring & Walkways

Checkered aluminum plates are widely used as industrial flooring in factories, workshops, and mechanical plants.

The non-slip pattern (such as diamond, 5-bar, or lentil) provides a secure walking surface even in environments with oil, dust, or moisture.

This makes it ideal for maintenance platforms, assembly areas, and production lines.

Its durability and low maintenance make it a long-term solution for high-traffic industrial zones.

Truck Bed Liners & Trailer Flooring

Aluminum checkered plate serves as a protective lining for truck beds, trailers, and cargo vehicles.

The raised tread pattern helps prevent cargo slippage during transport and reduces surface abrasion.

Lightweight yet tough, it improves fuel efficiency while providing impact and corrosion resistance under heavy-duty use.

Stair Treads & Steps

In industrial and commercial staircases, the embossed aluminum sheet is used for stair treads and risers to enhance safety.

The checkered texture increases traction under wet or oily conditions, making it perfect for factory stairs, fire escapes, and construction access points.

It can also be cut or bent to custom dimensions for modular stair systems.

Ramps & Walkways

Embossed aluminum is also used on loading ramps, walkways, and pedestrian passages for anti-skid performance.

It ensures safe footing for workers and vehicles, even in outdoor or humid environments.

Patterns like 5-bar or diamond embossing enhance grip, and 5052 alloy versions offer superior corrosion resistance for long-term outdoor exposure.

Vehicular & Transportation Applications

Used extensively in bus steps, RV floors, ship decks, and truck trailers, the tread aluminum plate provides both safety and aesthetic appeal.

Its lightweight structure minimizes total vehicle weight while maintaining high mechanical strength.

Aluminum’s recyclability and corrosion resistance make it a sustainable choice for transportation design.

Decorative & Architectural Design

Beyond functional use, checkered aluminum sheets also serve decorative roles in interior and exterior architecture.

They are used for wall panels, ceilings, counters, and accent cladding in commercial spaces such as restaurants, showrooms, and offices.

The embossed pattern adds texture and a modern industrial aesthetic, while anodized or colored finishes enhance visual appeal and durability.

DIY & Custom Fabrication Projects

Thanks to its formability and easy machinability, aluminum tread plate is popular in DIY, workshop, and fabrication projects.

It can be easily cut, drilled, or riveted to create toolboxes, ramps, garage walls, or shelves.

The durable, slip-resistant surface makes it a favorite among makers and custom fabricators.

Alloy Recommendations by Application

| Application Area | Recommended Alloy | Reason / Advantage |

| Industrial Flooring / Stair Treads | 3003, 5052 | Excellent formability and corrosion resistance |

| Vehicle Flooring / Trailer Bed | 5052, 5083 | High strength, lightweight, anti-corrosion |

| Decorative Panels / Indoor Use | 1100, 3003 | Smooth surface, easy polishing, aesthetic finishes |

| Marine / Outdoor Use | 5052, 5754 | Saltwater corrosion resistance |

| DIY / Light Fabrication | 1060, 3003 | Cost-effective and easy to machine |

Embossing / Manufacture Process

Base Coil Preparation — cleaning, degreasing, leveling

Embossing Rollers — pressed by rollers with pattern (diamond, 5-bar, stucco) under controlled pressure

Back Treatment / Flattening — ensure stability on underside

Surface Treatment (Optional) — anodizing, coating, painting

Slitting / Sheet Cutting — cut or slit to width, make stair panels

Inspection & Packaging — check pattern depth uniformity, edge quality, packaging for transport

Embossing not only adds texture but enhances stiffness and anti-slip performance.

FAQ

Q: What emboss patterns are available and which is best for stairs?

A: Common patterns include diamond, 5-bar, and stucco. Diamond and 5-bar offer high traction and are preferred for stairs and ramps.

Q: Which alloy is most suitable for embossed anti-slip aluminum?

A: Alloys like 3003 and 5052 are popular due to their balance of strength, corrosion resistance, and embossing performance.

Q: Does embossing affect corrosion resistance?

A: Embossing is mechanical and doesn’t reduce corrosion resistance. When combined with anodizing or coating, the surface remains well protected.

Q: Can this material be used outdoors?

A: Yes, especially when surface-treated (anodized or coated), it resists weathering and maintains performance.

Q: How do I clean anti-slip embossed aluminum?

A: Use mild detergent and soft brush; avoid strong acids or abrasives that could erode pattern crest.