| Specification | Description |

| Alloy Type | The alloy determines properties like strength, corrosion resistance, and formability. Common series: 1000, 3000, 5000, 6000. |

| Thickness | Thickness ranges from thin (0.2mm) to thick coils (over 3mm), affecting strength and application suitability. |

| Width | Available in widths between 100mm and 1500mm, based on the required application. |

| Temper | Indicates hardness: O (soft), H14/H16/H18 (medium-hard), T6 (high strength after heat treatment). |

| Surface Finish | Options include mill finish, anodized, and painted, affecting both aesthetics and performance. |

| Corrosion Resistance | Corrosion resistance varies by alloy; 5000 Series is highly resistant, especially in marine environments. |

| Weldability | 6000 Series alloys are preferred for welding, providing excellent strength and weldability. |

| Formability | Soft alloys like 1000 Series are easier to form, while harder alloys like 2000 Series provide superior strength but less formability. |

Aluminum Coil Classification: Types, Applications, and Finishes

Aluminum coils are categorized based on several key factors such as alloy type, application, surface treatment, thickness, and processing method. Each classification caters to specific industrial and commercial needs, ensuring you find the right aluminum coil for your project, whether it's for construction, automotive, packaging, HVAC, or marine applications.

By Alloy Type

Aluminum alloys are classified into series based on their main alloying elements. The most common classification is by series:

1000 Series: Pure aluminum, excellent corrosion resistance.

3000 Series: Aluminum-manganese, good for general-purpose use.

5000 Series: Aluminum-magnesium, ideal for marine and transportation.

6000 Series: Aluminum-magnesium-silicon, great for construction and structural applications.

8000 Series: Miscellaneous alloys, typically used for specific, non-structural applications.

By Application

Aluminum coils are often categorized based on the industries and applications they are used for.

Automotive: Used for body panels, engine components, and lightweight structures.

Construction: Applied in roofing, siding, cladding, and facades.

Packaging: Common in food cans, aluminum foil, and flexible packaging.

HVAC: Used in air conditioning systems and heat exchangers.

Marine: Best for boat hulls and offshore structures.

Electrical and Electronics: Electrical conductors, transformers, and capacitors.

By Surface Treatment

The surface treatment of aluminum coils plays a major role in their functionality and aesthetic appeal.

Mill Finish: Basic, uncoated, ideal for industrial use.

Anodized: Offers extra corrosion resistance and aesthetic appeal.

Painted: Provides weather resistance and color options.

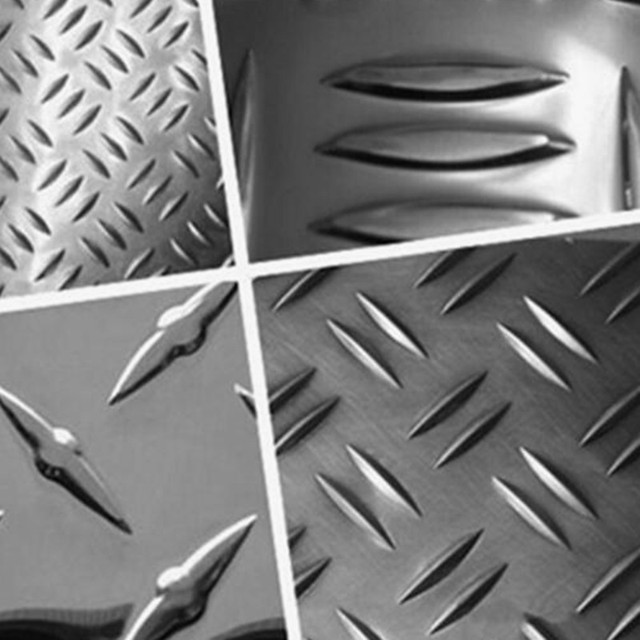

Embossed: Features patterns for added slip resistance and aesthetic purposes.

Color-Coated: Aluminum coils with a coating that can be custom-colored, providing both aesthetic appeal and weather resistance.

By Thickness and Size

The thickness and size of aluminum coils are critical for their intended application:

Thin Aluminum Coils: Usually used for packaging or decorative applications (e.g., aluminum foil, food packaging). Thickness: Typically from 0.2mm to 1mm.

Medium Thickness Coils: Common for construction, HVAC, and automotive industries. Thickness: Typically 1mm to 3mm.

Thick Aluminum Coils: Used for industrial and structural applications, offering higher strength and durability. Thickness: 3mm and above.

By Processing Type

Some aluminum coils are processed further before being shipped to customers:

Slit Coils: Coils that are slit to specific widths, often used in manufacturing.

Cut-to-Length Coils: Coils cut into fixed-length sheets for specific applications.

Flat Rolled Coils: Rolled to a smooth, flat surface, suitable for various end products.

| Aluminum Series | Alloy Types | Properties | Typical Applications | Surface Finishes |

| 1000 Series | 1050, 1060, 1070, 1100 | Excellent corrosion resistance, high thermal/electrical conductivity, low strength | Electrical, chemical, food processing, and decorative applications | Mill finish, anodized, painted |

| 2000 Series | 2011, 2014, 2017, 2024, 2036, 2018 | High strength, good machinability, poor corrosion resistance | Aerospace, military, automotive, structural components | Mill finish, anodized, painted |

| 3000 Series | 3003, 3004, 3005, 3105, 3A21 | Good corrosion resistance, good formability, moderate strength | Roofing, siding, HVAC systems, cooking utensils | Mill finish, painted, anodized |

| 4000 Series | 4032, 4045, 4045, 4052 | Low melting point, good weldability, moderate strength | Automotive parts, heat exchangers, welding rods | Mill finish, anodized, painted |

| 5000 Series | 5005, 5052, 5083, 5754 | Excellent corrosion resistance, high strength, especially in marine environments | Marine, transportation, pressure vessels, architectural applications | Mill finish, anodized, painted |

| 6000 Series | 6061, 6082 | Good strength, excellent weldability, excellent corrosion resistance | Structural applications, bridges, pipelines, aerospace | Mill finish, anodized, painted |

| 8000 Series | 8006, 8008, 8011 | Generally used for packaging and industrial applications, varying strength | Packaging (e.g., foil), industrial and electrical applications | Mill finish, anodized, painted |

Detailed Features & Applications Overview

1000 Series - Pure Aluminum

The 1000 series is composed of pure aluminum (typically 99% or higher). This series is known for its excellent corrosion resistance, high thermal and electrical conductivity, and low strength. It’s one of the most cost-effective aluminum grades.

Key Characteristics:

Electrical & Thermal Conductivity: Due to its high purity, the 1000 series is commonly used in electrical applications like transformers and capacitors.

Formability: This series is highly malleable and can be easily formed into a variety of shapes, making it ideal for applications that require a lot of forming and shaping.

Excellent Corrosion Resistance: Particularly in industries where resistance to chemicals and environmental stress is essential.

2000 Series - Aluminum-Copper Alloys

The 2000 series is an aluminum-copper alloy group, providing higher strength compared to the 1000 and 3000 series. However, it is less corrosion-resistant. These alloys are widely used in industries requiring strong, lightweight materials.

Key Characteristics:

High Strength: The 2000 series alloys provide some of the highest strength in aluminum, particularly 2024, which is a key material in aerospace and military applications.

Weldability: While strong, the copper content can reduce weldability in this series, and special techniques may be required to weld these alloys effectively.

Heat Treatable: These alloys can be heat-treated to further increase strength, making them suitable for applications requiring performance under stress.

3000 Series - Aluminum-Manganese Alloys

The 3000 series aluminum is primarily composed of manganese, offering excellent corrosion resistance and good formability. It’s a popular choice for general-purpose applications and is commonly used in architectural and construction applications.

Key Characteristics:

Corrosion Resistance: It excels in environments with high humidity or exposure to water.

Medium Strength: While not as strong as the 2000 series, it offers a good balance between strength and flexibility.

Formability: This series is well-known for its ability to be easily formed into various shapes.

4000 Series - Aluminum-Silicon Alloys

The 4000 series alloys are characterized by their addition of silicon, which lowers the melting point and enhances the material’s weldability. It’s often used in applications where welding is critical, and it also has a lower density.

Key Characteristics:

Low Melting Point: Ideal for welding, making it a great choice for applications that require frequent or extensive welding.

Good Flowability: Due to its lower melting point, it can easily be formed into molds or used in high-volume production environments.

Wear Resistance: While not as corrosion-resistant as some other series, the silicon content gives it a degree of wear resistance.

5000 Series - Aluminum-Magnesium Alloys

The 5000 series aluminum, containing magnesium as the primary alloying element, is known for its excellent corrosion resistance, especially in marine environments. It’s one of the most commonly used grades for products exposed to harsh conditions.

Key Characteristics:

Corrosion Resistance: Particularly resistant to seawater and other corrosive environments.

High Strength-to-Weight Ratio: It’s strong but remains lightweight, making it perfect for applications where weight is a critical factor.

Weldability: Unlike the 2000 series, the 5000 series is easily weldable, especially for marine and construction applications.

6000 Series - Aluminum-Magnesium-Silicon Alloys

The 6000 series alloys are a combination of magnesium and silicon, offering a great balance of strength, formability, and corrosion resistance. This series is versatile, commonly used in a wide range of applications..

Key Characteristics:

Balanced Properties: It has a perfect balance between strength and formability, making it one of the most versatile aluminum grades.

Excellent Weldability: It is commonly used in structural applications requiring welding.

Medium to High Strength: Offers a higher strength-to-weight ratio than the 3000 and 4000 series, making it suitable for a wide range of industries.

8000 Series - Miscellaneous Alloys

The 8000 series is a collection of aluminum alloys that don't belong to the major alloy series (1000-6000). These alloys are typically used for specialized purposes, such as packaging and electrical conductors.

Key Characteristics:

Versatility: The alloys in the 8000 series are used for a wide range of applications, from packaging to electrical cables.

Cost-Effective: These alloys are generally less expensive than the higher-performance grades but still offer significant performance in specific applications.

Varied Properties: The properties can vary widely, so each alloy in this series is chosen based on its specific use case.

Benefits of Using Aluminum Coils

Lightweight Yet Strong

Aluminum is incredibly lightweight compared to many other metals, making it easier to handle and transport. Despite its lightness, it provides a strong and durable structure, particularly when used in the 6000 Series alloys for construction and machinery.

Exceptional Corrosion Resistance

Aluminum coils, particularly from the 5000 Series, have high corrosion resistance, even in harsh environments like marine and chemical settings.

Excellent Formability and Workability

Aluminum coils are easy to form, even in intricate shapes, without losing their strength. Alloys like 3000 Series and 1000 Series are especially well-suited for forming processes like rolling, stamping, and punching.

Recyclability

Aluminum is a highly recyclable material. Once it is used, it can be reprocessed into new products with minimal loss in quality.

Thermal and Electrical Conductivity

Aluminum has excellent thermal and electrical conductivity, which is why it’s often used in applications like heat exchangers, electrical conductors, and HVAC systems.

Aesthetic Appeal and Customization

Aluminum coils can be painted, anodized, or embossed, providing custom colors and textures. This gives you the flexibility to match aesthetic needs without compromising on durability.

Aluminum Coil Applications Across Industries

Alloys: 3000 Series, 5000 Series, 6000 Series

Aluminum coils for roofing is widely used in both residential and commercial buildings.

Aluminum coil for wall cladding and industrial aluminum coil are essential in creating durable and weather-resistant exteriors.

Gutter systems: Aluminum gutter coil, white gutter coil, and gutter aluminum coil are used in the production of gutters, offering excellent durability and resistance to corrosion.

Trim Applications: Aluminum trim coil, fascia trim coil, and window trim coil add finishing touches to roofing and window structures, enhancing both aesthetics and functionality.

How to Choose the Right Aluminum Coil Series?

Provide an overview of how to select an appropriate series based on factors like strength, formability, corrosion resistance, and industry application.

Strength Requirements

For heavy-duty structural components, you may prefer 5000 Series or 6000 Series. For lighter applications, 3000 Series might be enough.

Corrosion Resistance

If you’re working in a marine environment, 5000 Series (5052, 5083) is best due to its superior corrosion resistance.

Formability & Weldability

If your project involves complex forming, 1000 Series or 3000 Series might be suitable. For welding-heavy applications, consider the 6000 Series.

Budget

For cost-effective solutions, 1000 Series or 3000 Series are often preferred for general-purpose use.

Manufacturing and Production Efficiency

Select 6000 Series for easy welding, 3000 Series or 1000 Series for forming, and 2000 Series for precision machining.

Environmental and Durability Considerations

Choose 5000 Series or 6000 Series for superior corrosion resistance, and 3000 Series for outdoor use with protective finishes.

Recommended Aluminum Coil Products for Your Projects

FAQ

Aluminum coils are used in a wide range of applications across industries due to their lightweight, corrosion-resistant, and versatile properties. Common uses include:

Construction: For roofing, siding, cladding, and trim applications.

Automotive: In vehicle body panels, engine parts, and structural components.

Packaging: In food and beverage cans, and aluminum foil.

HVAC: In heat exchangers and air conditioning coils.

Electrical: For wiring and conductors in transformers.

Request a Quote for Your Aluminum Coil Needs

Looking for the perfect aluminum coil for your project? We’ve got you covered!

Fill out the form to receive a personalized quote, tailored to your specific requirements. Whether you need customized sizes, special coatings, or fast delivery, our team is ready to assist you with the best options for your business needs.

Mob:+86-18086775436

E-mail:info@yqalu.com