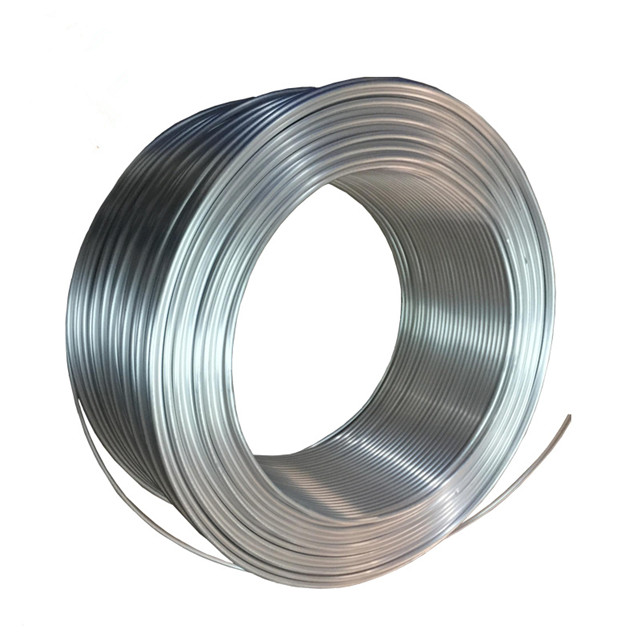

Aluminum Tubing Coil – Seamless Coil for HVAC / Heat Pump / Automotive Thermal Systems

High Thermal Conductivity | Lightweight | OEM-Grade Reliability

Aluminum tubing coil is a key heat exchange material widely used in HVAC systems, heat pumps, automotive thermal management, refrigeration units, and cold chain cooling systems.

Compared with copper, it offers outstanding thermal efficiency, energy-saving performance, corrosion resistance, and lightweight structure, making it suitable for large-scale manufacturing and OEM supply.

Aluminum tube is a kind of high strength duralumin, which can be strengthened by heat treatment. It has medium plasticity under annealing, hardening and hot state, and good weldability in spot welding. Aluminum tube has a tendency to form intergranular cracks during gas welding and argon arc welding. The machinability of aluminum tube is good after quenching and cold hardening, but poor in annealing state. Corrosion resistance is not high, often using anodic oxidation treatment and painting method or surface coated with aluminum layer to improve the corrosion resistance. Can also be used as a mold material.

![tube tube]()

Surface treatment of Aluminum Tube

Chemical treatment: oxidation, electrophoretic coating, fluorine carbon spraying, powder spraying, wood grain transfer

Mechanical treatment: mechanical drawing, mechanical polishing, sandblasting.

| Treatment | Method | Engineering Benefit |

| Chemical | anodizing · electrophoresis · powder coat · fluorocarbon · hydrophilic | corrosion resistance / enhanced heat transfer |

| Mechanical | sandblasting · brushing · polishing | smoother fit / bonding improvement |

| OEM-level | degreasing / anti-oxidation coating | brazing-friendly & assembly-ready |

Advantages of Aluminum Tube

✅ Excellent welding technology: suitable for industrial production of thin-wall copper aluminum pipe welding technology, known as a world-class problem, is the key technology of air conditioner connection pipe aluminum copper replacement.

✅ Longer service life: from the inner wall of the aluminum pipe, because the refrigerant does not contain moisture, the inner wall of the copper and aluminum connection pipe will not corrod.

✅ Energy saving: the connection pipeline between the indoor unit and the outdoor unit of the air conditioner, the lower the heat transfer efficiency, the more energy saving, or the better the heat insulation effect, the more power saving.

✅ Excellent bending performance, easy to install and move.

YUQI Aluminum Tube Specifications

Packagin

| Tube Size | OD(MM)

| Wall Thickness(mm) | Material | Packaging |

| Φ4.76 | 0.8 | 1050 1060 1100 3003 3102 H112 | All the products are put on the strong wooden pallet. Each pallet can load 1-2tons.

|

| Φ6.0 | 0.7,0.75,1.0 |

| Φ6.35 | 0.5,0.6,0.75,0.8,1.0 |

| Φ6.5 | 0.75 |

| Φ7.0 | 0.7,0.75,0.8,1.0 |

| Φ7.5 | 0.7,0.75 |

| Φ8.0 | 0.5,0.65,0.7,0.8,0.9,1.0 |

| Φ12.0 | 1.0,1.2 |

| Φ12.7 | 0.65,0.8,1.0,1.15,1.2 |

Alloy & Specification Overview

| Item | Range / Options |

| Alloy | 1050 / 1060 / 1070 / 1100 / 3003 / 3102 / 5052 |

| Thickness | 0.2–2.0 mm |

| OD | 4.76–12.7 mm (customizable) |

| Temper | O / H14 / H24 |

| Coil Form | pancake / oscillated / layer-wound |

| Surface | mill · degreased · hydrophilic · anodized |

| Application Fit | HVAC / heat pump / auto / cold-chain |

Alloy Selection Guide

| Alloy | Thermal | Strength | Formability | Recommended For |

| 1050 / 1060 | ★★★★★ | ★★ | ★★★★ | HVAC base coils |

| 3003 / 3102 | ★★★★ | ★★★ | ★★★★ | heat pump & cycle fatigue |

| 5052 | ★★★★ | ★★★★★ | ★★★ | automotive & vibration |

| 1100 | ★★★★ | ★★ | ★★★★ | refrigeration general duty |

![tube2 tube2]()

Mechanical properties

| Tensile strength(Mpa) | Elongation (%) |

| 60-90 | ≥30 |

Chemicial Composition (%)

| Temper | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other | Al |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | --- | 0.05 | 0.03 | 0.03

| Remain |

| 1060 | 0.20

| 0.25 | 0.03

| 0.03 | 0.03 | --- | 0.03 | 0.03 | 0.03 | Remain |

| 1070 | 0.20

| 0.25 | 0.04

| 0.03 | ---

| --- | 0.04 | --- | 0.03 | Remain |

1100

| 0.95

| 0.05-0.20 | 0.05 | --- | --- | --- | 0.10

| 0.03 | Remain |

| 3003 | 0.60 | 0.70 | 0.05-0.20 | 1.00-1.50 | --- | --- | 0.10 | --- | 0.15

| Remain |

3102

| 0.60 | 0.70 | 0.30

| 0.30-0.80 | 0.20-0.80

| 0.20

| 0.40 | --- | 0.15 | Remain |

Application Scenarios & Use Cases

| Industry | Functional Role | Key Benefit |

| HVAC Systems (evaporator / condenser) | heat transfer | excellent conductivity & easy forming |

| Heat Pumps (outdoor / monoblock / R290) | refrigerant circulation | low weight boosts COP |

| Automotive Cooling | EV battery / AC / exhaust | vibration resistance · lightweight |

| Refrigeration / Ice-making | continuous cycle cooling | stable performance, anti-corrosion |

FAQ

Q1: Is aluminum tubing good for HVAC coils?

Yes. Aluminum tubing provides excellent heat transfer efficiency, low weight, easy bending, and better cost-effectiveness than copper in large-scale HVAC manufacturing.

Q2: What alloy of aluminum is best for heat pumps?

3003 and 3102 are most commonly used due to their superior freeze–thaw fatigue resistance and stable performance in long operating cycles.

Q3: Can aluminum tubing replace copper in air conditioners?

Yes, when the correct wall thickness and surface treatment are applied (such as degreasing/hydrophilic coating), aluminum is a proven replacement in both AC and heat pump systems.

Q4: Is aluminum tubing suitable for automotive thermal management?

Yes, especially 5052 alloy for EV battery cooling and heat exchangers, due to its high strength-to-weight ratio and vibration resistance.

Q5: What is the difference between hydrophilic and mill finish tubing?

Hydrophilic coating improves condensation drainage and anti-frost performance; mill finish is untreated aluminum used in non-condensing applications.

Q6: Can aluminum tubing be brazed?

Yes — with the correct alloy and degreased surface. Brazing-quality aluminum tubing is widely used in OEM evaporator and condenser production.

Q7: Does aluminum tubing corrode in refrigerant systems?

No. Refrigerant systems are closed and moisture-free, so internal corrosion does not occur — one major reason aluminum is ideal for long service life.

Q8: What is the minimum bending radius for aluminum tubing?

Depending on alloy and temper, typically 2–3× OD for annealed tube, which enables complex routing in compact equipment.

Engineering CTA

Looking for OEM-grade aluminum tubing coil with full technical support?

Contact us for datasheet, forming guidance, and sample evaluation.

[Request A Quote]

Classification of Aluminium Tube

According to the shape: square pipe, round pipe, pattern pipe, shaped pipe, global aluminum pipe.

According to the extrusion method: seamless aluminum tube and ordinary extrusion tube

According to the accuracy: ordinary aluminum tubes and precision aluminum tubes, of which precision aluminum tubes generally need to be reprocessed after extrusion, such as cold drawing and rolling.

According to the thickness: ordinary aluminum tube and thin-walled aluminum tube.

Property: Corrosion resistance, light weight.