![Why Does Aluminum Coil Curl After Cooling from High Temperatures]()

You notice that aluminum coil curls after cooling from high temperatures. This happens because aluminum contracts unevenly as it cools. Different parts of the aluminum coil lose heat at different rates. Shrinkage forces pull the coil into a curled shape. You see this effect in industries like construction and automotive. Yuqi Metal offers aluminum coil products that show these behaviors. The question "Why Does Aluminum Coil Curl After Cooling from High Temperatures?" helps you understand how aluminum responds to heat. Aluminum is lightweight and flexible. You find aluminum in HVAC systems and packaging. Aluminum remains strong and reliable after cooling.

Key Takeaways

Aluminum coils curl after cooling due to uneven contraction. Different parts cool at different rates, causing stress and warping.

Gradual cooling is crucial. It helps maintain uniform temperature across the coil, reducing the risk of curling and permanent deformation.

Thinner aluminum coils cool faster and show less curling. Choose the right thickness based on your project needs to improve performance.

Environmental factors affect cooling rates. Windy conditions cool surfaces quickly, while humid areas slow down cooling. Consider these when cooling aluminum.

Controlled cooling methods, like air cooling, help manage shape and stress in aluminum coils. This leads to better dimensional accuracy.

Material treatments like annealing relieve internal stress. This process improves flexibility and helps prevent curling in aluminum coils.

Understanding the impact of coil shape and manufacturing methods can help reduce curling. Customize diameter and length for specific applications.

Quality control during production is essential. Spot defects early to ensure flat, reliable aluminum coils that meet industry standards.

Heat Effects on Aluminum Coil

![Heat Effects on Aluminum Coil]()

When you heat an aluminum coil, you see clear changes in its structure and properties. These changes happen because of thermal expansion and the way atoms move inside the metal. You need to understand these effects to control the quality of your aluminum products.

Expansion During Heating

Atomic Movement

As you raise the temperature, the atoms in aluminum start to vibrate more. This movement pushes the atoms farther apart. You notice the coil gets longer and wider. This process is called thermal expansion. The thermal expansion coefficient for pure aluminum is about 23.1 x 10⁻⁶ °C⁻⊃1;. This means that for every degree Celsius increase, the coil expands by 23.1 millionths of its original length. Different aluminum alloys, like those from Yuqi Metal, may show slightly different thermal expansion rates because of their unique compositions.

Temporary Shape Change

Thermal expansion does not change the coil forever during heating. You see the coil stretch or grow, but it returns to its original size when it cools down, unless the temperature gets extremely high. The expansion is temporary at this stage. If you use a 5000 or 6000 series alloy from Yuqi Metal, you may notice that the coil handles thermal expansion better because these alloys resist deformation at high temperatures.

High Temperature Impact

Softening

When you expose aluminum to high temperatures, the metal softens. The bonds between atoms weaken, and the coil becomes easier to bend or shape. You see a drop in strength and an increase in ductility.

The research on the 4043 Al alloy reveals that prolonged exposure to high temperatures results in reduced strength and increased elongation, particularly after repeated thermal cycles, which is critical for applications in high-temperature environments.

You can use this property to form the coil into different shapes, but you must control the process to avoid unwanted changes.

Stress Build-up

Thermal expansion also causes stress inside the coil. As the outside and inside of the coil heat up at different rates, you get uneven expansion. This creates internal stress. If you look at the table below, you see how deformation force drops as temperature rises:

Temperature (°C) | Deformation Force Reduction (%) |

20 | N/A |

40 | 15 |

These changes in mechanical properties help you understand why stress builds up in aluminum coils during thermal expansion. If you use Yuqi Metal’s 3000 or 6000 series alloys, you benefit from better heat resistance, which helps reduce unwanted stress and deformation.

Cooling Process Impact

![Cooling Process Impact]()

When you cool an aluminum coil after heating, you see changes in its shape and structure. The cooling process determines how the coil behaves. You must understand cooling rate differences and heat dissipation to control the final product.

Cooling Rate Differences

Surface vs. Core

You notice that the surface of the aluminum coil cools faster than the core. The outside loses heat quickly because it touches the air or water directly. The core stays hot longer. This difference in cooling rates creates uneven contraction. The surface shrinks first, while the core follows later. You see curling because the coil cannot contract evenly. If you choose a thicker coil from Yuqi Metal, the core takes more time to cool. Thinner coils cool faster and show less curling.

Environmental Influence

The environment affects cooling. If you cool the coil in a windy area, the surface loses heat faster. In a humid or still environment, cooling slows down. You must consider the surroundings when cooling aluminum. Yuqi Metal offers coils with different finishes. A painted or anodized surface changes how fast the coil cools. These finishes help you control the cooling rate and reduce curling.

Heat Dissipation

Air vs. Water Cooling

You can cool aluminum coils using air or water. Air cooling is slower. The coil loses heat gradually. Water cooling is faster. The coil drops in temperature quickly. Fast cooling increases the risk of curling because the surface contracts before the core. Slow cooling lets the coil shrink more evenly. You must choose the right cooling method for your project. Yuqi Metal provides coils with various thicknesses. Thicker coils need careful cooling to avoid curling.

Controlled Cooling

Controlled cooling helps you manage the shape and stress in aluminum coils. You use gradual cooling to keep the temperature uniform. This prevents local heat shrinkage and improves the final shape. Studies show that controlled cooling in cold forging ensures uniform temperature distribution. You get better dimensional accuracy and less curling. Yuqi Metal offers customization for thickness and finishes. You select the best options to match your cooling needs. Controlled cooling gives you a reliable coil with fewer defects.

Tip: Choose gradual cooling and the right surface finish to minimize curling in aluminum coils.

You see that cooling methods, environmental factors, and coil properties all affect curling. Yuqi Metal’s customization options help you control these factors and produce high-quality aluminum coils.

Why Does Aluminum Coil Curl After Cooling from High Temperatures?

You often ask, why does aluminum coil curl after cooling from high temperatures? The answer lies in the way aluminum reacts to heat and cooling. When you heat aluminum, it expands. When you cool it, it contracts. This process does not happen evenly across the coil. You see warping and curl because different parts of the coil change size at different rates.

Uneven Contraction

Thermal Contraction

You notice that thermal contraction plays a big role in why does aluminum coil curl after cooling from high temperatures? As the coil cools, the temperature drops faster on the outside than on the inside. The surface contracts first. The core stays hot and contracts later. This difference creates stress. You see the coil start to curl or warp as a result.

Thermal shock causes mechanical stresses in aluminum.

Rapid cooling makes the surface shrink before the core.

Nonuniform temperature changes lead to warping and curl.

You can compare this to pouring cold water on a hot glass. The outside contracts quickly, but the inside stays expanded. The glass can crack or warp. Aluminum behaves in a similar way, but instead of cracking, you see curling and warping.

Material Response

Aluminum responds to these stresses by changing shape. The metal tries to relieve the stress caused by uneven contraction. You see the coil curl because the material cannot shrink evenly. Warping happens when the forces inside the coil push and pull in different directions. The coil bends or twists to balance these forces. This is why does aluminum coil curl after cooling from high temperatures? You see this effect more in coils with large temperature differences between the surface and the core.

Shrinkage Forces

Edge vs. Center

You notice that the edges of the coil cool and contract faster than the center. The outside loses heat to the air or water. The center stays warm longer. This creates a tug-of-war inside the coil. The edges pull in, while the center resists. You see the coil curl outward or inward, depending on which side contracts more. Warping becomes visible as the coil tries to balance these shrinkage forces.

Internal Stress

Internal stress builds up as the coil cools. You see this stress as warping or curl in the final product. The surface experiences tensile stress because it wants to shrink faster. The core feels compressive stress because it cools more slowly. These stresses do not cancel each other out. Instead, they cause the coil to bend or twist. This is another reason why does aluminum coil curl after cooling from high temperatures? You must control cooling rates to reduce warping and curl in aluminum coils.

Tip: You can reduce warping by using gradual cooling methods. This helps the entire coil contract at a similar rate.

You see that why does aluminum coil curl after cooling from high temperatures? The answer involves uneven contraction, thermal contraction, material response, shrinkage forces, and internal stress. You can manage these factors to produce flatter, more reliable aluminum coils. Warping and curl are common challenges, but you can minimize them with the right process.

Factors Influencing Curling

You see several factors that influence curling in aluminum coils. Understanding these factors helps you select the right product for your project. Yuqi Metal offers customization options for thickness, shape, and alloy series. You can choose the best aluminum coil for construction, automotive, or HVAC applications.

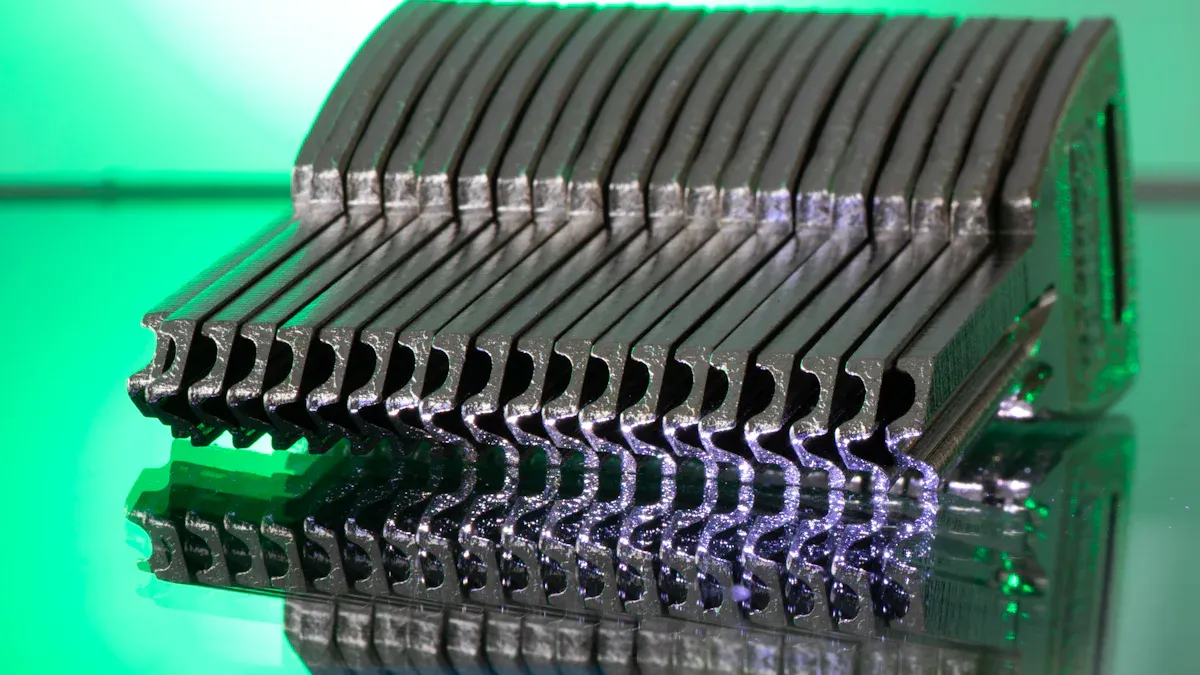

Coil Thickness

Thin vs. Thick

Thickness plays a major role in curling. Thin aluminum coils cool quickly. You notice less curling because the temperature stays more uniform across the coil. Thick coils take longer to cool. The surface cools faster than the core. This difference causes uneven contraction and more curling. You can select the thickness that fits your needs. Yuqi Metal provides coils from 0.2mm to over 3mm. If you work in packaging, you often use thin coils. For roofing or siding, you may need thicker coils. Choosing the right thickness reduces curling and improves performance.

Tip: Thinner coils show less curling after cooling. Thicker coils need careful cooling to avoid warping.

Coil Shape

Diameter and Length

Shape affects curling as well. You see that coils with larger diameters or longer lengths experience more stress during cooling. The edges cool and contract faster than the center. This creates a tug-of-war inside the aluminum coil. You notice curling at the edges or along the length. Yuqi Metal allows you to customize diameter and length. If you need coils for HVAC systems, you may prefer smaller diameters. For construction, larger coils are common. Adjusting shape helps you control curling and match your application.

Manufacturing Methods

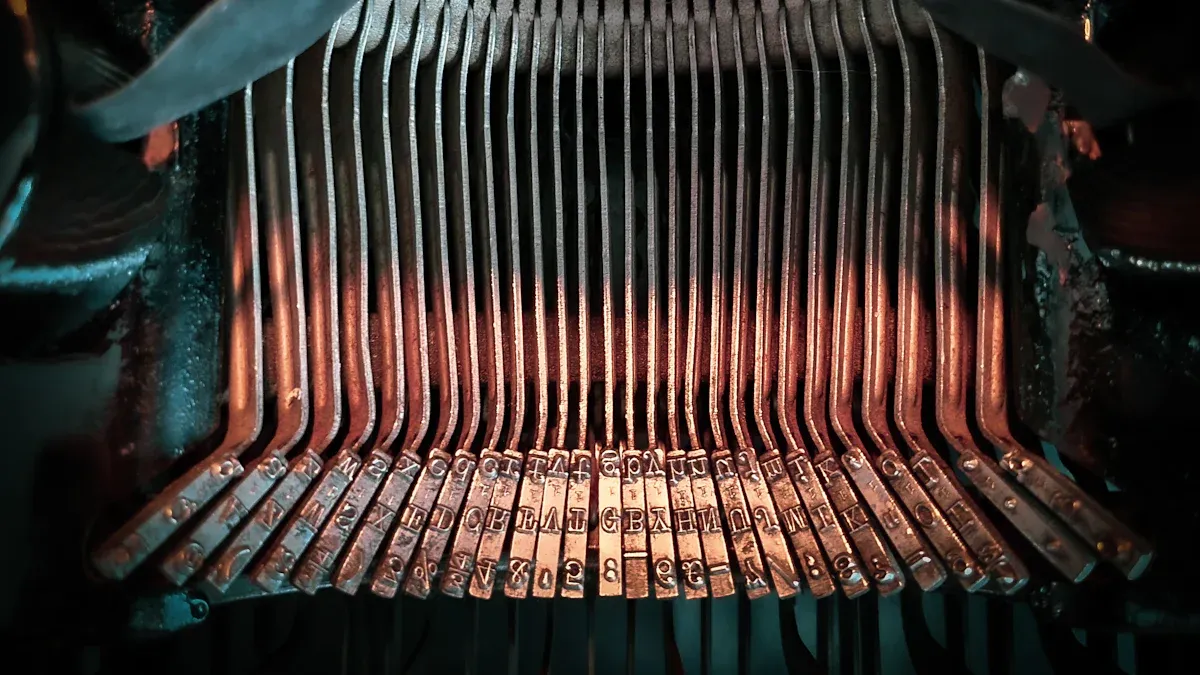

Rolling Techniques

Rolling techniques during manufacturing impact curling. You see that uneven stretching in the transverse direction leads to distortion. The edges of the aluminum plate stretch more than the center. This causes curling and affects flatness. Roller deformation and improper roller crown increase stretching from edges to center. Excessive roller crown creates rapid waves in the middle of the coil. You may notice upward curling of the edges when you place the plate on a flat surface. Internal stress imbalance and uneven thickness also contribute to curling.

Rolling Technique Factor | Curling Effect |

Uneven edge stretching | Distortion and loss of flatness |

Roller deformation | Increased edge-to-center stretch, more curling |

Excessive roller crown | Rapid waves in coil center |

Uneven thickness deformation | Internal stress imbalance, curling |

You can choose aluminum coils from Yuqi Metal with precise rolling techniques. This reduces curling and improves quality. Different industries require different manufacturing methods. Automotive applications need flat coils for body panels. Construction uses coils with specific shapes and thicknesses. HVAC systems benefit from coils with controlled stress and minimal curling.

Note: Customizing thickness, shape, and manufacturing methods helps you minimize curling in aluminum coils for any application.

Stress Distribution and Curling

Internal Stress

When you cool an aluminum coil, you see internal stress develop inside the metal. This stress comes from the way different parts of the coil lose heat at different speeds. You notice that thin sections cool faster than thick sections. The result is a thermal gradient across the coil. This gradient creates uneven shrinkage forces. Some areas contract more than others. You see the coil bend or curl as it tries to balance these forces.

Thermal gradient forms as aluminum cools.

Thin-walled sections cool and contract faster.

Differential shrinkage forces appear between thin and thick areas.

Uneven internal stress distribution leads to curling toward thicker sections.

Stress Release

You observe that internal stress must find a way to release. If the stress stays trapped, the coil will curl or bend. The metal tries to reach a stable shape. You see the coil twist or warp as the stress moves from one area to another. Sometimes, the coil settles into a new shape after cooling. You can reduce stress release problems by controlling the cooling rate. Gradual cooling helps the coil shrink evenly. You get a flatter coil with fewer defects.

Note: Managing cooling speed and coil thickness helps you control internal stress and reduce curling.

Curling Mechanism

Curling happens when the stress inside the aluminum coil causes permanent changes in shape. You see the coil bend or twist as it cools. The metal cannot return to its original form because the stress has changed its structure.

Permanent Deformation

Permanent deformation means the coil keeps its curled shape even after cooling. You notice this effect when the stress inside the coil becomes too strong. The metal stretches or compresses in certain areas. The coil bends to relieve the stress. You see this most often in thick coils or coils with uneven cooling. Once the coil curls, you cannot easily flatten it without extra treatment. You can prevent permanent deformation by using gradual cooling and choosing the right coil thickness. Yuqi Metal offers aluminum coils with options that help you avoid curling and keep your products in top shape.

Tip: Select the proper cooling method and coil thickness to minimize permanent deformation in aluminum coils.

Prevention and Solutions

You can prevent aluminum coil curling by using several practical methods. These approaches help you achieve a flatter coil and improve product quality. Yuqi Metal supports you with quality control and product options that minimize curling.

Controlled Cooling

Gradual Cooling

Gradual cooling stands as one of the most reliable ways to reduce curling in aluminum coils. You slow down the cooling process so the temperature drops evenly across the coil. This method lowers internal stress and prevents warping. You can use cooling techniques such as air cooling or controlled environments to achieve gradual cooling. When you apply effective cooling, you allow the coil to contract at a uniform rate. This reduces the risk of permanent deformation.

Tip: Gradual cooling helps you maintain the shape of aluminum coils and ensures consistent quality.

Material Treatments

Annealing

Annealing offers another solution for preventing curling. You heat the aluminum coil to a specific temperature and then cool it slowly. This process relieves internal stress and improves flexibility. Annealing makes the metal softer and easier to shape. You can use this treatment after rolling or forming the coil. Yuqi Metal provides aluminum coils that undergo annealing for better performance. When you combine annealing with effective cooling, you get a coil that resists curling and stays flat.

Treatment Method | Benefit |

Annealing | Relieves stress, improves flexibility |

Gradual Cooling | Reduces warping, maintains shape |

Design Adjustments

Engineering Solutions

Engineering solutions help you address curling during the design phase. You can adjust coil thickness, diameter, and length to match your application. You select the right alloy series for your needs. Yuqi Metal offers customization options so you can choose the best aluminum coil for construction, automotive, or HVAC projects. You can also use advanced cooling techniques to control the temperature during manufacturing. These adjustments ensure that your coil stays flat and performs well in its intended use.

Note: You improve coil quality by combining design adjustments with proper cooling techniques and material treatments.

You see that prevention and solutions involve gradual cooling, annealing, and engineering adjustments. Yuqi Metal’s quality control and product options help you minimize curling and deliver reliable aluminum coils for every industry.

Real-World Implications

Manufacturing Impact

Quality Control

You play a key role in maintaining quality control during the production of aluminum coils. When you understand how curling happens, you can spot defects early. You check each coil for flatness and shape before it leaves the factory. If you see curling, you know that uneven cooling or internal stress caused the problem. You use this knowledge to adjust your process. For example, you might slow down the cooling rate or choose a different alloy. Yuqi Metal supports you with advanced inspection tools and strict quality standards. You can rely on these systems to deliver consistent results.

Note: Quality control helps you reduce waste and improve efficiency in your manufacturing line.

You also see how aluminum coil quality affects your reputation. Customers expect reliable products for construction, automotive, and HVAC projects. When you provide flat, defect-free coils, you build trust with your clients. Yuqi Metal’s wide range of coil options lets you meet different industry needs. You can select the right thickness, finish, and alloy for each application.

Product Performance

Usability

You notice that curling impacts the usability of aluminum coils in real-world projects. If a coil curls too much, you may find it hard to install or shape. This can slow down your work and increase costs. For example, in roofing or siding, you need flat coils for a smooth finish. In HVAC systems, you want coils that fit tightly for better energy efficiency. When you use coils from Yuqi Metal, you get products designed for easy handling and installation.

You also care about sustainability. Aluminum stands out as a recyclable material. When you use high-quality coils, you reduce the need for rework and scrap. This saves resources and lowers your environmental impact. Yuqi Metal’s commitment to eco-friendly production means you support green practices with every project.

Here is a quick look at how curling affects your work:

Application | Impact of Curling | Solution from Yuqi Metal |

Construction | Uneven surfaces | Custom thickness and finishes |

Automotive | Poor panel fit | Precision rolling |

HVAC | Reduced efficiency | Flat, easy-to-install coils |

Tip: Choose the right coil for your project to improve performance and support sustainability.

You see that understanding aluminum coil curling helps you deliver better products and protect the environment. Yuqi Metal gives you the tools and options to succeed in every industry.

You see that aluminum coil curling happens because uneven contraction and internal stress shape the metal as it cools. Manufacturers and users benefit from understanding these effects. You improve coil performance by choosing gradual cooling, annealing, and smart design. Yuqi Metal offers aluminum coil solutions that help you reduce curling and achieve reliable results. Explore the product range to find the best aluminum coil for your project.

Tip: Selecting the right aluminum coil and cooling method ensures better quality and usability.

FAQ

What causes aluminum coil curling after cooling?

You see aluminum coil curl because different parts cool at different speeds. Uneven contraction creates internal stress. The coil bends or twists to relieve this stress.

How can you prevent aluminum coil curling?

You prevent curling by using gradual cooling, choosing the right thickness, and applying treatments like annealing. Yuqi Metal offers coils with options that help reduce curling.

Does coil thickness affect curling?

Yes. Thin coils cool faster and show less curling. Thick coils cool slowly, which increases the risk of curling. You select thickness based on your project needs.

Which industries use aluminum coils from Yuqi Metal?

You find Yuqi Metal aluminum coils in construction, automotive, packaging, and HVAC. Each industry benefits from customized thickness, finishes, and alloy types.

Can you recycle aluminum coils?

Absolutely! Aluminum coils are highly recyclable. You support sustainability by choosing Yuqi Metal products, which help reduce waste and promote eco-friendly manufacturing.

What cooling methods work best for aluminum coils?

Gradual air cooling works best for most coils. Water cooling is faster but increases curling risk. You choose the method based on coil thickness and application.

Why do edges curl more than the center?

Edges cool and contract faster than the center. This creates a tug-of-war inside the coil. You see curling at the edges as the metal tries to balance shrinkage forces.

How does Yuqi Metal ensure coil quality?

Yuqi Metal uses strict quality control, advanced inspection tools, and customizable options. You receive reliable coils with minimal curling for every industry application.