Product Overview

Our Anodized Aluminum Sheets and Oxidized Aluminum Coils are designed for refrigeration, HVAC, and freezer applications, where corrosion resistance, thermal stability, and surface protection are essential.

Through advanced anodizing and oxidation treatments, the aluminum surface forms a dense oxide layer that protects against moisture, chemical exposure, and mechanical wear, ensuring long-term durability in cooling environments.

Available in coil and sheet forms, 1000 and 3000 series alloys, and with customizable oxide thickness, this product is ideal for refrigerator inner panels, evaporators, condensers, and HVAC housings.

⚙️ Anodized Aluminum Manufacturing Process

The anodizing process is an electrochemical surface treatment that thickens and stabilizes the natural oxide film on aluminum.

It enhances hardness, corrosion resistance, and appearance without affecting the metal’s thermal conductivity.

Step-by-Step Process:

Surface Cleaning & Degreasing – removes oil and contaminants.

Alkaline Etching / Acid Pickling – lightly dissolves surface to ensure uniform texture.

Anodizing (Electrolytic Oxidation) – aluminum acts as the anode in an acid electrolyte (usually sulfuric acid).

Coloring (Optional) – the porous oxide layer can absorb dyes or metal salts for decorative finishes.

Sealing – pores are closed by hot water or nickel acetate sealing, enhancing corrosion resistance and preventing contamination.

Inspection & Drying – final quality checks on thickness, adhesion, and surface finish.

Typical Anodic Film Thickness:

✅ Result: Anodized aluminum has a hard, corrosion-proof, non-conductive oxide layer that preserves metal shine while providing protection and color stability.

Oxidized Aluminum vs. Anodized Aluminum — What’s the Difference?

| Aspect | Oxidized Aluminum | Anodized Aluminum |

| Process Type | Natural or chemical oxidation | Electrochemical oxidation (controlled) |

| Oxide Film Thickness | 0.01–0.1 µm (natural thin film) | 3–25 µm (dense, engineered film) |

| Hardness / Durability | Moderate | 2–3× harder surface, scratch-resistant |

| Corrosion Resistance | Limited | Excellent (sealed anodic pores) |

| Appearance | Matte grey or dull silver | Uniform bright or colored finish |

| Applications | General aluminum protection | High-end applications — refrigeration, architecture, electronics |

| Maintenance | More prone to oxidation marks | Easy to clean, non-staining |

| Cost | Lower | Slightly higher but longer lifespan |

✅ All anodized aluminum is oxidized, but not all oxidized aluminum is anodized.

Anodizing is a controlled, enhanced oxidation process that produces a much thicker and stronger oxide layer — ideal for refrigeration, HVAC, and industrial aluminum panels where corrosion resistance and appearance matter.

Aluminum Sheet vs. Aluminum Coil — Choosing the Right Form

| Property | Aluminum Sheet | Aluminum Coil |

| Form | Flat plate (cut to size) | Continuous rolled strip wound into coils |

| Thickness Range | 0.2 – 6 mm | 0.1 – 3 mm (thinner range) |

| Common Uses | Refrigerator inner liners, wall panels, signage | Continuous production — evaporator fins, condenser panels |

| Processing | Easier for small batch cutting, stamping, shaping | Ideal for automated continuous fabrication or coating lines |

| Storage / Handling | Individual sheet packaging | Coil form for easy transport and rewinding |

| Surface Treatment | Can be anodized or painted | Can be pre-anodized or coated before slitting |

| Cost Efficiency | Higher for small runs | More efficient for bulk production |

✅ Selection Tip:

Use anodized aluminum coil for continuous panel fabrication or refrigeration production lines,

and cut aluminum sheet for custom freezer walls, panel replacements, or decorative covers.

Material & Technical Specifications

| Parameter | Range / Options | Description |

| Alloy Grades | 1050, 1060, 1100, 3003 | Excellent anodizing quality and corrosion resistance |

| Temper | O / H14 / H24 | For forming or bending requirements |

| Thickness | 0.2 – 3.0 mm | Customizable |

| Width | ≤ 1600 mm | Coil or sheet cutting available |

| Oxide Film Thickness | 3 – 25 µm | Optional per environment |

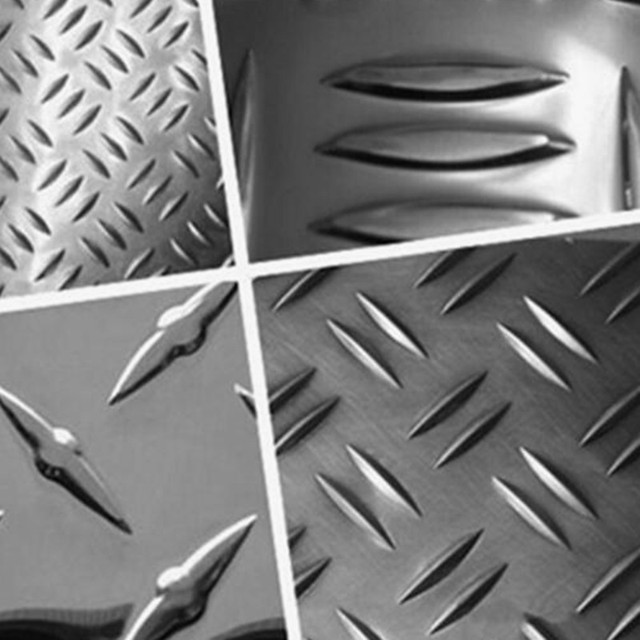

| Finish Options | Smooth / matte / brushed / embossed | Decorative or functional texture |

| Surface Color | Silver, champagne, black, custom | Optional dyed anodizing |

| Corrosion Resistance | Excellent — salt spray > 500 hrs | Tested for refrigeration conditions |

Application Scenarios

Refrigerator Inner Panels & Lining Coils – corrosion-proof surface resists condensation and cleaning agents.

Evaporator & Condenser Fin Material – excellent heat transfer and oxidation resistance.

HVAC Components – housings, ducts, insulation panels with anodized surface protection.

Freezer Cabinets & Display Units – aesthetic and durable interior finish.

Food Storage & Cold Chain Equipment – hygienic, easy-to-clean, anti-corrosive surface.

Why Choose Anodized Aluminum for Refrigeration?

Strong corrosion resistance in moisture and chemical cleaning environments

High surface hardness (HV 200+) and scratch resistance

Long-term color stability and brightness

Maintains excellent thermal conductivity

Eco-friendly and recyclable — no paint or harmful coatings

Easy fabrication — bending, stamping, or bonding

FAQ

Q1: What’s the difference between anodized and oxidized aluminum for refrigeration?

A: Oxidized aluminum forms a thin natural oxide film, while anodized aluminum undergoes a controlled electrochemical process that produces a thicker, harder oxide layer for superior protection.

Q2: Does anodizing reduce heat transfer in refrigeration?

A: Only minimally. The oxide film is thin (< 25 µm) and doesn’t significantly impact aluminum’s high thermal conductivity.

Q3: Which alloy is best for anodized aluminum sheet in refrigeration?

A: 1060 and 3003 alloys provide excellent anodizing response and corrosion resistance, making them ideal for refrigerator panels and HVAC coils.

Q4: Can anodized aluminum be used in contact with food?

A: Yes. Properly sealed anodized surfaces are food-safe and resistant to staining and odor absorption.

Q5: Can I use coils and sheets interchangeably?

A: Use coils for large continuous production; use sheets for custom panels or replacement parts.