Product Overview

YUQI Metal has full production machines to supply anodized orange peel embossed aluminum sheets, which are mainly used in cold storage, freezers, color-coated embossed stucco aluminium coil for home appliance panel decoration, embossed corrugated sheets for roofs, anti-corrosion coated embossed aluminum sheets for air-conditioning pipes, and patterns coils are used in machinery platforms, automotive road skid coil industries, etc.

Key Features:

Material: 1050, 1060, 3003, 3105 Aluminum Alloy.

Surface Treatment: Anodized, Color-Coated, or Protective Film.

Thickness: 0.10–0.12 mm embossing layer.

Width: 100–1500 mm.

Hardness: H14, H16, H18, H24.

Properties: Water-resistant, Wear-resistant, Anti-pollution, Corrosion-resistant.

Applications: Refrigeration interiors, Air-conditioning ducts, Roof decoration, Industrial platforms.

Technical Specifications

| Alloy | Thickness (mm) | Width (mm) | Hardness | Surface Treatment | Features |

| 1050 | 0.10–0.12 | 100–1500 | H14–H24 | Anodized, Color-Coated, Film | Corrosion & Wear Resistant |

| 1060 | 0.10–0.12 | 100–1500 | H14–H24 | Anodized, Color-Coated, Film | Anti-Pollution |

| 3003 | 0.10–0.12 | 100–1500 | H14–H24 | Anodized, Color-Coated, Film | Water & Corrosion Resistant |

![C1111 C1111]()

Stucco Embossed Aluminum Coil Surface Finish

![AE AE]()

Anodized stucco embossed

aluminum coil

![CE CE]()

Color-coated embossed

aluminum coil

![KE KE]()

Kraft paper clad stucco embossed

aluminum coil

Anodized stucco embossed aluminum coil

Anodized surface-treated orange peel embossed aluminum sheet with a thin layer of aluminum oxide formed on the surface.

| YUQI Alloy | 1050, 1060, 1100,3003 ,3105 anodized embossed aluminum coils |

| Anodizing Thickness | ≥3μm |

| Embossing Thickness | 0.10-0.12mm |

| Hardness | H14,H16,H18,H24 |

| Width | 100-1500mm

|

| Characteristics | waterproof, wear-resistant, anti-fouling, corrosion resistance, etc |

| Application | used to decorate the interior of refrigerators and the exterior of cooling systems |

Color-coated embossed aluminum coil

The color-coated embossed aluminum coil is also called embossed color coated coil. Its surface is coated with one or several layers of polyester, fluorocarbon and varnish through the roller coater.

| YUQI Alloy | 1050,1060,1100,3003, 3105,5052 color-coated embossed aluminum coil |

| Thickness | 0.10-0.12mm |

| Hardness | H14,H16,H18,H24 |

| Width | 100-1500mm |

| Embossed Pattern | color-coated orange peel pattern, color-coated diamond pattern, etc |

| Application | often used in decoration, cabinets, and home appliance panels |

Kraft paper clad stucco embossed aluminum coil

The aluminum coil is hot-compressed with kraft paper, and then de-embossed. After embossing, its strength and anti-corrosion performance are further enhanced.

It is mainly used for anti-corrosion and thermal insulation projects, and is exported to foreign customers, especially the pipeline thermal insulation projects of Middle East Petroleum.

Manufacturing technology of stucco embossed aluminum coil

Embossed aluminum coil is a flat aluminum coil, which is rolled by embossing roller and forms various embossed patterns on its surface. The surface is treated with anodic oxidation, color coating, film coating or kraft paper lamination.

① Melting and Holding furnace - High-purity aluminum alloys (1050, 1060, 3003, 3105) are melted in temperature-controlled furnaces to ensure uniformity.

② Cold Rolling -The molten aluminum is rolled into flat coils with precise thickness control, preparing the material for embossing.

③ Stretch and Straighten - Coils are stretched and straightened to eliminate internal stress, ensuring a smooth surface and consistent thickness.

④ Acid Wash, then Dry - The surface is cleaned using acid washing to remove impurities, followed by drying to prepare for embossing and coating.

⑤ Embossing Production - Special embossing rollers imprint stucco or custom patterns onto the aluminum surface, creating a textured and visually appealing finish.

⑥ Surface Treatment - The embossed coil is treated with anodizing, color coating, protective film, or kraft paper lamination to enhance corrosion resistance, durability, and aesthetic appeal.

⑦ Cutting and Packing - Finished coils are cut to customer-specified dimensions, carefully packed, and prepared for shipment.

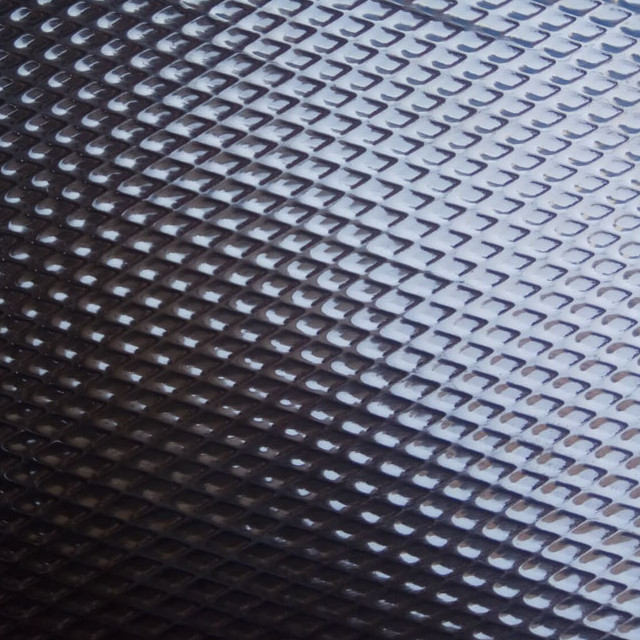

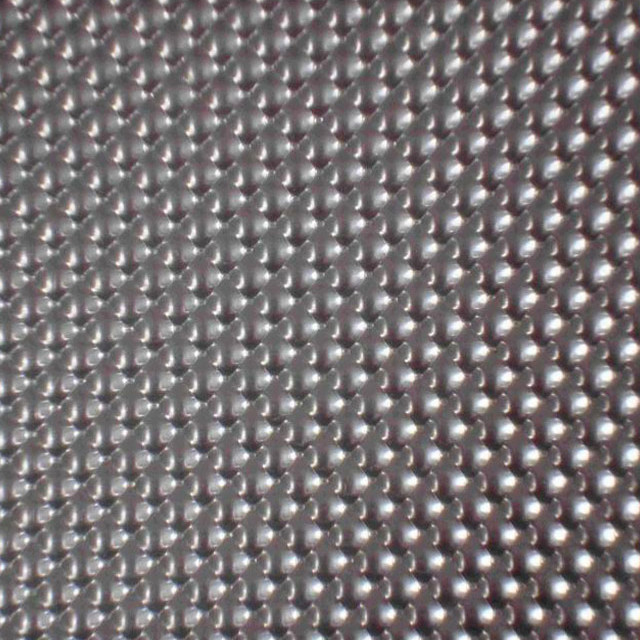

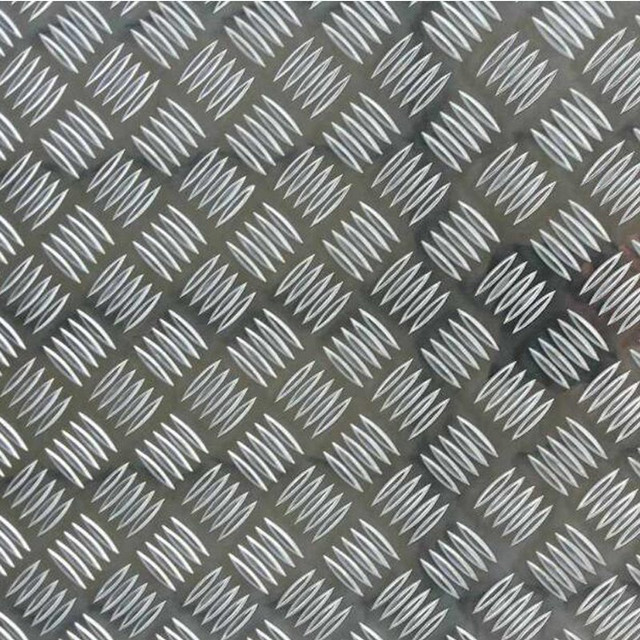

Stucco Embossed Aluminum Pattern

![peel1 peel1]()

![diamond diamond]()

![Hemispherical Hemispherical]()

![pointer pointer]()

![tread tread]()

Orange Peel Rhombus Hemisphere Diamond Five Bars

Why choose YUQI Metal stucco embossed aluminum coil?

Strong Strength

"YUQI Metal" has become the leading aluminum products supplier in different industries such as home appliance industry, construction industry, packaging industry, transportation etc.

Professional Team

Our team has undergone strict skill training and has rich experience in products and markets. We required quick response to customer demands within 1hour. You can save time and get comprehensive one-stop service from us.

Factory Coordination Speed

All departments of the factory are perfect, including production department, quality department,finance

department, business department, purchasing department etc. The responsibilities of each department are clearly divided, which can quickly respond to customer needs.

Flexible Business

More flexible cooperation methods, you can get more possibility from us.

Reliable Packaging

Strong wooden pallet or box or customer required.

Frequently Asked Questions (FAQ)

Q1: What is a stucco embossed aluminum coil?

A: A stucco embossed aluminum coil is a flat aluminum coil processed with embossing rollers to create textured patterns on its surface. It can be finished with anodic oxidation, color coating, film coating, or kraft paper lamination for durability, aesthetic appeal, and corrosion resistance.

Q2: What are the common applications of embossed aluminum sheets?

A: Embossed aluminum sheets and coils are widely used in:

Roofing and wall panels

HVAC ducts and air-conditioning systems

Refrigeration interiors and cold storage

Industrial platforms and machinery

Decorative and architectural projects

Q3: What is the difference between anodized and color-coated aluminum coils?

A: Anodized aluminum coils have a protective oxide layer that enhances corrosion resistance and surface hardness. Color-coated aluminum coils have a painted layer that provides both protection and decorative appeal. Many stucco embossed aluminum coils combine embossing with these treatments for maximum durability and aesthetics.

Q4: Can embossed aluminum coils be customized?

A: Yes. You can customize pattern type, thickness, width, alloy (1050, 1060, 3003, 3105), and surface treatment to meet your project requirements.

Q5: How is the quality of stucco embossed aluminum coils ensured?

A: Our coils go through a strict production process: melting, cold rolling, stretch and straighten, acid washing, embossing, surface treatment (anodizing or coating), cutting, and packing. Each step ensures consistent thickness, surface texture, and durability.

Q6: What thicknesses and widths are available?

A: Standard stucco embossed aluminum coils are available in 0.10–0.12 mm thickness and 100–1500 mm width, but custom dimensions can be produced based on your project needs.

Q7: How do I know which type of embossed aluminum coil is right for my project?

A: Consider your project’s requirements:

Durability and corrosion resistance: choose anodized aluminum coil

Decorative and color options: choose color-coated aluminum coil

Slip resistance or texture requirement: choose stucco embossed patterns

Q8: What is the minimum order quantity (MOQ)?

A: The typical MOQ for stucco embossed aluminum coil is 500 kg per order, but it may vary depending on alloy, thickness, and surface treatment.

Q9: How long does it take to deliver embossed aluminum coils?

A: Standard delivery time is 15–25 days, depending on order quantity and customization. Worldwide shipping is available.

Q10: How should I store stucco embossed aluminum coils?

A: Keep the coils in a dry, ventilated environment. Avoid direct contact with corrosive chemicals and heavy objects that may damage the embossed surface.

Q11: Are there any environmental or safety considerations?

A: Our embossed aluminum sheets and coils are made from recyclable aluminum, and all surface treatments are environmentally friendly. They comply with industrial safety and environmental standards.

Q12: Can embossed aluminum sheets be used outdoors?

A: Yes. Stucco embossed aluminum coils with anodized or color-coated finishes are highly resistant to corrosion and UV exposure, making them suitable for outdoor applications like roofing, wall cladding, and exterior décor.