Key Specifications

Alloy & Temper: 1050, 1060 (H14/H24)

Thickness: 0.3–3.0 mm (stock: 0.5 / 0.8 / 1.0 / 1.2 mm)

Width: 1000 / 1200 / 1250 / 1500 mm (custom available)

Surface Pattern: Orange Peel Embossed

Standards: ASTM B209, EN 485, GB/T 3880

Finishes: Mill finish / Anodized / PE or PVC film-coated

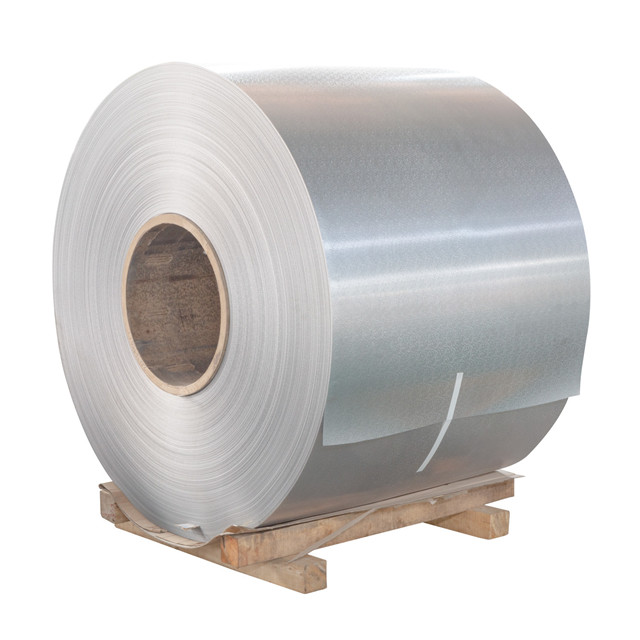

Supply Form: Coil or flat sheet

MOQ: 3 tons per size

Lead Time: 3–5 days (stock), 7–15 days (custom)

Thermal Conductivity: ~230 W/m·K

Tensile Strength: 60–100 MPa (depending on temper)

Elongation: 20–30%

Density: 2.71 g/cm³

Application Scenario of Embossed Aluminum Coil Sheet for Evaporator

The Orange Peel Embossed Aluminium Coil and Sheet is widely applied across multiple industries thanks to its combination of lightweight strength, corrosion resistance, and decorative surface. The orange peel pattern not only provides an attractive appearance but also delivers functional benefits such as improved rigidity, scratch hiding, and anti-slip performance.

Evaporator in Refrigeration Systems

The Embossed Aluminum Coil Sheet is utilized as a key component in evaporators for refrigeration systems. The embossed surface of the aluminum coil sheet enhances heat transfer efficiency by increasing the surface area for better contact with the refrigerant. This results in faster cooling and improved overall performance of the evaporator. The high-quality aluminum material ensures durability and resistance to corrosion, making it ideal for long-term use in refrigeration applications. The precise design and construction of the embossed aluminum coil sheet contribute to the efficient operation of the evaporator, providing reliable cooling for various refrigeration systems. One of the most common applications is in evaporators and refrigeration panels. The embossed surface helps improve airflow and reduces condensation buildup, making it an excellent material for cold storage rooms, beverage coolers, supermarket display cabinets, and ice makers.

Evaporator in HVAC & Air Conditioning Units

In HVAC applications, the embossed coil is used in air handling units, ductwork, and heat exchangers. The increased stiffness allows for thinner gauges without sacrificing strength, lowering overall system weight and cost.

The Embossed Aluminum Coil Sheet is essential for the functionality of evaporators in air conditioning units. The embossed surface of the aluminum coil sheet maximizes heat transfer efficiency, allowing for rapid cooling of the air passing through the evaporator. This results in effective temperature regulation and enhanced comfort in indoor spaces. The durable aluminum material ensures longevity and resistance to corrosion, making it a reliable component for air conditioning applications. The precise engineering of the embossed aluminum coil sheet ensures optimal performance of the evaporator, contributing to the overall efficiency of air conditioning units.

Cold Chain Logistics

In the logistics sector, orange peel embossed aluminium is used in refrigerated trucks, containers, and cold boxes. Its light weight reduces overall vehicle load while maintaining durability, helping to lower fuel costs and improve energy efficiency in transportation.

Food & Beverage Industry

Hygiene and easy cleaning are critical in food and beverage facilities. These embossed sheets are ideal for food processing plants, commercial kitchens, and brewery cooling systems, where corrosion resistance and a clean surface are essential.

Pharmaceutical & Biotech Storage

Pharmaceutical and biotech industries require temperature-stable storage chambers and clean rooms. Orange peel embossed aluminium provides both durability and compliance with hygiene standards, making it suitable for sensitive storage environments.

Orange Peel Embossed vs. Plain Aluminum Sheet

| Feature | Orange Peel Embossed Aluminium Sheet | Plain Aluminum Sheet |

| Surface Appearance | Textured “orange peel” pattern, decorative finish | Smooth, flat, simple surface |

| Rigidity / Strength | Higher stiffness, less prone to dents | Lower stiffness, more easily deformed |

| Scratch Resistance | Hides scratches and minor surface damage | Scratches easily visible |

| Slip Resistance | Provides anti-slip effect on surface | No anti-slip property |

| Applications | Refrigeration panels, evaporators, decorative use | General construction, flat panels |

Manufacturing Process

Production starts with high-purity 1050/1060 aluminum slabs that are hot rolled and cold rolled into thin coils. The cleaned surface is passed through precision embossing rollers to create the orange peel texture. This embossed finish not only improves stiffness but also delivers a distinctive decorative effect. Optional treatments such as anodizing or film coating provide additional protection. Finished coils and sheets are then slit, cut-to-size, inspected, and packaged for export.

Packaging & Logistics

Export-standard wooden pallets with waterproof wrapping.

Edge protection and paper interleaving.

Container loading capacity: up to 20–23 tons per 20GP container.

FAQ

Q1: Why use Orange Peel Embossed Aluminum in evaporators?

Because it combines excellent heat transfer performance with corrosion resistance and rigidity, making it ideal for refrigeration and HVAC systems.

Q2: What thickness is typically used for evaporators?

Common thicknesses are between 0.5 mm and 1.2 mm, but other sizes up to 3.0 mm are available.

Q3: Do you supply coils as well as sheets?

Yes, we supply both continuous coils for industrial processing and flat sheets for direct installation.

Q4: What surface protection options are available?

We offer PE/PVC film lamination and anodizing for improved durability and scratch protection.

Q5: What certifications can you provide?

Each order comes with a Mill Test Certificate. SGS testing and RoHS/REACH compliance can also be provided.

Q6: Can I order a trial quantity?

Yes, while the standard MOQ is 3 tons per size, smaller trial orders may be discussed for new clients.

Q7: Do you export worldwide?

Yes, we ship to Europe, the Middle East, Southeast Asia, South America, and other major markets.