![7 Common Defects in Color-Coated Aluminum Coils and Tips to Prevent Them]()

Quality plays a vital role in the performance of color-coated aluminum coils across industries such as construction, automotive, and packaging. You often encounter several defects that can affect coil reliability. The most common problem areas include:

Surface scratches

Color difference

Poor adhesion

Pinholes

Edge wave

Low gloss

Delamination & waviness

Yuqi Metal uses quality assurance measures and quality assurance testing to deliver premium coils. You can follow Precautions for Using Color-Coated Aluminum Coils to prevent defects during production and handling.

Key Takeaways

Surface scratches can occur during handling and storage. Always handle coils with care to prevent damage.

Color differences can affect product quality. Use consistent raw materials and monitor the coating process closely.

Poor adhesion leads to peeling and flaking. Ensure proper surface preparation and use compatible coatings.

Pinholes are tiny defects that can compromise the coating. Maintain a clean production environment to minimize impurities.

Edge wave affects coil usability. Control tension during production to keep coils flat and prevent deformation.

Low gloss reduces visual appeal. Prepare surfaces well and monitor coating quality to maintain shine.

Delamination and waviness can impact performance. Focus on adhesion and rolling parameters to prevent these defects.

Regular inspections are crucial. Check coils for defects before use to ensure high quality and reliability.

Surface Scratches

![Surface Scratches]()

Defect Overview

Surface scratches represent one of the most frequent defects you may encounter with color-coated aluminum coils. These scratches can occur at any stage, from manufacturing to handling and storage. They often result from contact with equipment, improper stacking, or careless movement. Surface scratches not only affect the appearance but can also compromise the protective coating, leading to further metal substrate defects and potential corrosion. You must address this problem early to maintain the quality and durability of your aluminum coil.

Cause | Description |

Friction with guides or equipment | This occurs during processing, leading to surface damage. |

Layer misalignment during annealing | Misalignment can cause scratches when uncoiling. |

Improper handling during finishing | Handling errors can result in scratches during packaging. |

Identification

You can identify surface scratches by visually inspecting the coil for lines, marks, or grooves that differ from the intended finish. These scratches may appear as shallow or deep marks, depending on the severity of the damage. If you notice a suspected defect, check for irregularities in the coating or exposed metal. Scratches often run parallel to the direction of the coil, making them easier to spot during routine inspections. Regular checks help you catch defects before they lead to more serious issues.

Prevention

Handling

Tip: Always handle aluminum coils with care to prevent accidental damage.

You can minimize defects by following best practices during storage and transport:

Ensure aluminum coils are clean and free of dirt or debris before packaging to avoid abrasions during transit.

Wrap coils tightly with stretch film to protect against dust, moisture, and other environmental factors.

Place wrapped coils on sturdy, defect-free pallets for even weight distribution.

Use corner protectors on the palletized load to prevent damage to coil edges during handling and transit.

Keep coiled strip in its original packaging until needed.

Ensure coils are tightly re-banded if storing eye-to-side to prevent scratching.

Store in a heated and humidity-controlled location to minimize waterstain risk.

Yuqi Metal recommends storing coils in a clean, dry environment and using proper lifting equipment. You should avoid stacking coils directly on top of each other. Regular inspections help you detect defects early and maintain coil quality.

Equipment Care

Proper equipment maintenance plays a key role in preventing surface scratches. Inspect guides, rollers, and conveyors for wear or sharp edges. Replace damaged parts immediately to avoid causing scratches during processing. Align layers correctly during annealing to prevent misalignment and reduce the risk of damage. Yuqi Metal follows strict quality standards and routine equipment checks to ensure coils remain free from defects. You can adopt similar practices to protect your coils and extend their lifespan.

Color Difference

![Color Difference]()

Defect Overview

Color difference is a common defect that you may notice in color-coated aluminum coils. This problem occurs when the color of the coating appears uneven or inconsistent across the coil surface. You might see this issue as patches, streaks, or shifts in shade. Color difference can affect the visual appeal and perceived quality of your finished product. It often results from variations in raw materials, inconsistent coating thickness, or changes in process conditions. If you do not address color difference, it can lead to customer complaints and reduce the value of your product.

Identification

You can identify color difference by comparing the coil surface under consistent lighting. Look for areas where the color appears lighter, darker, or different from the standard. You may also use industry standards and tools to measure and confirm color consistency. The following table lists some of the most widely used standards for identifying color difference and related defects in color-coated aluminum coils:

Standard | Description |

ECCA T3 | Color range for color-coated aluminum coils |

ECCA T2 | Gloss degree specifications |

ECCA T1 | Coating thickness requirements |

ECCA T4 | Pencil hardness standards |

ASTM D3359 | Adhesion testing method |

ASTM D2794 | Impact resistance testing method |

GB/T17748 | Boil resistance testing method |

ASTM D2248 | Solvent resistance testing method |

ASTM D1308 | Acidity resistance testing method |

If you find a suspected defect, compare the coil to a reference sample or use a spectrophotometer for precise measurement.

Precautions for Using Color-Coated Aluminum Coils

Material Consistency

You can prevent color difference by choosing consistent raw materials. Select aluminum coils from the same batch and supplier whenever possible. Yuqi Metal offers a wide range of alloy types and surface finishes, which helps you minimize color variation. By using coils with similar chemical composition and surface treatment, you reduce the risk of color mismatch. Always check the batch number and finish type before starting production.

Process Control

Process control plays a key role in avoiding color difference. You should monitor every step of the coating process. Inline color measurement systems can evaluate color quality across the entire coil. The ERX145 Inline Spectrophotometer measures color on hot coated surfaces and accounts for temperature changes. Real-time feedback allows you to make immediate adjustments and maintain color consistency.

To further reduce defects, pay attention to these process factors:

Anodic coating thickness

Anodizing process type (such as 2-step or integral color)

Solution type and concentration

Solution temperature

Type of etch used

Time spent in each process step

Load size and racking method

Current density variation

Tip: Regularly calibrate your measurement tools and keep detailed records of process parameters. This helps you trace and correct any color difference quickly.

By following these precautions, you can maintain high quality and avoid metal substrate defects caused by color inconsistency in your color-coated aluminum coils.

Poor Adhesion

Defect Overview

Poor adhesion stands out as a critical defect in color-coated aluminum coils. You may notice that the coating fails to bond properly with the aluminum surface. This issue can lead to peeling, flaking, or blistering. When the coating separates, the coil becomes vulnerable to environmental damage. Poor adhesion often results from improper surface preparation, contamination, or incorrect application methods. You must address this defect to maintain the quality and durability of your product. If you ignore poor adhesion, you risk exposing the coil to corrosion and other metal substrate defects.

Identification

You can identify poor adhesion by inspecting the coil for signs of peeling or flaking. Use a simple tape test to check film adhesion. Apply adhesive tape to the coated surface and pull it away sharply. If the coating lifts or cracks, you have a clear indication of defective metal. Look for bubbles, blisters, or areas where the coating appears loose. These defects signal that the bond between the coating and the aluminum is weak. Regular inspection helps you catch this defect early and prevent further damage.

Tip: Always check for visible signs of separation or blistering before using color-coated aluminum coils in your project.

Prevention

Pretreatment

You can prevent poor adhesion by preparing the aluminum surface carefully. A clean and smooth surface is essential for coating adhesion. Inspect the surface for defects such as scratches, pits, or oil residues. Remove all contaminants using appropriate cleaning methods. Many manufacturers now use chromate-free and phosphate-free pretreatment compositions. These environmentally friendly options provide corrosion resistance equivalent to traditional coatings. You protect both the coil and the environment by choosing these advanced pretreatments.

Clean the aluminum thoroughly before applying any coating.

Inspect for defects and repair any scratches or pits.

Use chromate-free or phosphate-free pretreatments for better corrosion resistance.

Coating Process

The coating process plays a major role in preventing poor adhesion. You must apply the coating evenly and at the correct thickness. Monitor the temperature and humidity during application. These factors affect how well the coating bonds to the aluminum. Use high-quality paint and follow the manufacturer’s guidelines. Yuqi Metal recommends regular process checks to ensure consistent results. You should also calibrate your equipment and maintain proper application speed.

Apply the coating in a controlled environment.

Check the thickness and uniformity of the coating layer.

Use reliable equipment and monitor process parameters closely.

Note: Consistent process control and surface preparation help you avoid defects and maintain high quality in color-coated aluminum coils.

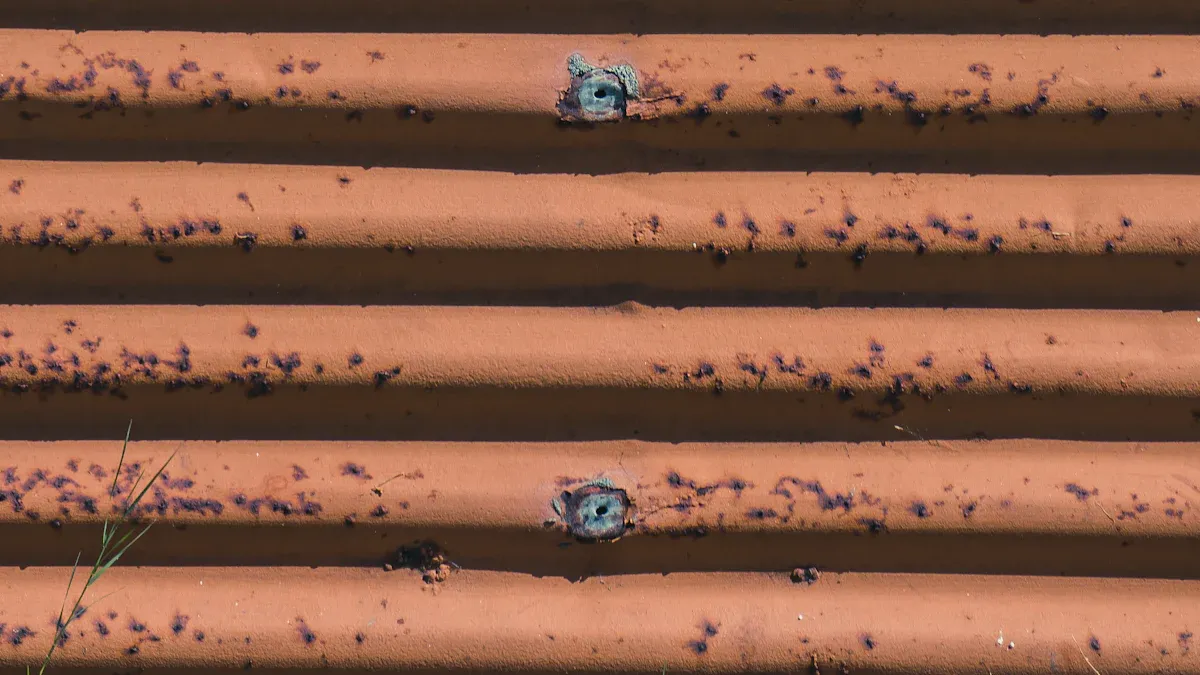

Pinholes

Defect Overview

Pinholes are tiny pores that can appear on the surface of color-coated aluminum coils. You may notice these small holes range from 5 μm to 50 μm in diameter. Pinholes often result from impurities in the raw aluminum, inconsistencies during the rolling process, or mechanical damage that occurs during manufacturing. These defects can compromise the protective barrier of the coating, allowing moisture or contaminants to reach the underlying metal. In sensitive applications, such as pharmaceutical packaging, even a single pinhole larger than 20 μm can allow contaminants to enter, which highlights the importance of preventing this defect.

Here is a summary of the main causes of pinhole formation:

Cause of Pinhole Formation | Description |

Impurities in Raw Aluminum | Exogenic and endogenic impurities, such as titanium diboride and silicates, significantly contribute to pinhole formation. |

Inconsistencies During Rolling | Variations in the rolling process can lead to defects, including pinholes. |

Mechanical Damage | Damage during manufacturing processes can create pinholes in the final product. |

You should understand that pinhole sizes and shapes vary depending on the types of impurities present. The mechanical properties of these impurities also influence how pinholes form. When you see pinholes, you are looking at a sign of defective metal that can affect the overall quality of your finished product.

Identification

You can detect pinholes by visually inspecting the coil surface under proper lighting. Look for tiny pores or holes that break the smoothness of the coating. Industry standards recommend a maximum of three pinholes per square meter for high-quality coils. For more precise detection, you can use advanced methods such as laser scanning, automated optical inspection (AOI), or 3D surface profilometry. These technologies allow you to measure surface variations in detail and identify even the smallest defects.

Detection Method | Description |

Visual Inspection Standards | Standards for identifying surface defects. |

Maximum allowable defects | ≤3 pinholes per m². |

Advanced Detection Methods | Includes laser scanning and automated optical inspection. |

Laser Scanning | Accuracy of ±0.01mm. |

Automated Optical Inspection (AOI) | Advanced technology for defect detection. |

3D Surface Profilometry | Measures surface variations in detail. |

Tip: Regular inspections using both visual and automated methods help you maintain high quality and prevent defective coils from reaching your customers.

Prevention

Application Technique

You can reduce pinholes by focusing on proper application techniques during the coating process. Start by ensuring the aluminum liquid is well purified and filtered before rolling. This step removes impurities that can cause defects. Use high-quality rolling oils and install a filtering system to minimize dust contamination. Adjust rolling conditions by increasing rolling force and reducing tension. These changes help create a smoother surface and fewer pinholes.

Purify and filter aluminum liquid before processing.

Use high-quality rolling oils and maintain clean equipment.

Adjust rolling force and tension for optimal results.

Environmental Control

Environmental factors also play a role in pinhole prevention. Keep the production area clean and control dust levels. Maintain stable temperature and humidity during the coating process. These steps help you avoid introducing new defects and ensure the coating forms a continuous, protective layer.

Clean the production environment regularly.

Monitor and control temperature and humidity.

Store coils in a dust-free, dry area after coating.

By following these best practices, you can minimize pinholes and maintain the quality of your color-coated aluminum coils.

Edge Wave

Defect Overview

Edge wave is a defect that you may encounter during the production of color-coated aluminum coils. This defect appears as undulations or wavy patterns along the coil edges. Edge wave can affect the flatness and usability of the coil. You may see this issue when the coil does not lay flat or when the edges rise above the center. Edge wave often results from uneven deformation during rolling or improper tension control. You must address edge wave early to maintain the quality of your finished product and prevent further defects such as coil camber, coil set, crossbow, or center buckle.

Identification

You can identify edge wave by inspecting the coil for visible waves or ripples along the edges. Place the coil on a flat surface and observe the profile. If the edges curve upward or downward compared to the center, you have detected edge wave. You may also notice that the coil does not fit properly in automated processing equipment. Edge wave can cause problems during cutting, slitting, or further coating applications. Regular inspection helps you catch this defect before it affects your production line.

Tip: Use a straightedge or measuring tool to check for edge wave. Compare the edge height to the center height to confirm the presence of this defect.

Prevention

Coil Tension

You can minimize edge wave by controlling coil tension during production. Proper tension ensures that the coil remains flat and prevents deformation. Adjust the tension settings on your rolling and winding equipment. Monitor tension levels throughout the process. If you notice changes in tension, make immediate adjustments. Tension leveling or temper rolling can help flatten and straighten wavy coils. These corrective measures improve coil quality and reduce defects.

Rolling Process

Optimizing the rolling process is essential for preventing edge wave. Focus on these strategies:

Adjust roll gap, rolling speed, and temperature to minimize uneven deformation.

Align and support the strip properly to prevent edge wave and other deformation phenomena.

Implement corrective measures such as tension leveling or temper rolling to flatten and straighten coils.

You should also check for other related defects like coil camber, coil set, crossbow, and center buckle. These issues often occur together with edge wave and can affect the performance of the coating. Yuqi Metal recommends routine process checks and equipment maintenance to ensure consistent results. By following these best practices, you maintain high quality and reduce the risk of edge wave in your color-coated aluminum coils.

Low Gloss

Defect Overview

Low gloss is a defect that affects the appearance and performance of color-coated aluminum coils. You may notice that the surface looks dull or lacks shine. This issue can reduce the visual appeal of your finished products. Low gloss often signals problems with the coating process or surface preparation. When gloss levels drop, you risk losing the aesthetic value and protective benefits of the coil. Many industries demand high gloss for architectural and decorative applications, so maintaining proper gloss is essential.

Identification

You can identify low gloss by comparing the coil surface to a reference sample under consistent lighting. Use a gloss meter to measure gloss levels accurately. The tolerance for gloss measurement is ±5, which helps you detect even small changes. Industry standards guide you in evaluating gloss levels for color-coated aluminum coils. The following table summarizes the main standards used:

Aspect | Details |

Gloss Measurement | Measured with a gloss meter (tolerance ±5) |

Standards | ASTM-B-209M, BS EN 485-2, GB/T3880-2008 |

If you see a dull finish or uneven shine, you have likely found a defect. Regular checks help you maintain consistent gloss and avoid defects that impact product quality.

Tip: Always measure gloss levels after the coating process to ensure your coils meet industry requirements.

Prevention

Surface Preparation

Proper surface preparation helps you prevent low gloss. Clean the aluminum substrate thoroughly before applying the coating. Remove oil, moisture, and dust to create a smooth base. Rough surfaces or contaminants can hinder gloss and cause defects. You should inspect the substrate for scratches or pits and repair them as needed. Yuqi Metal recommends using advanced cleaning methods to achieve a flawless surface. Consistent preparation ensures that the coating bonds well and delivers the desired gloss.

Clean the substrate to remove oil and dust.

Repair scratches or pits before coating.

Inspect surfaces for roughness and contaminants.

Coating Quality

You can improve gloss by focusing on coating quality. Mix paint thoroughly before application to avoid uneven gloss. Avoid excessive pigment, filler, or solvent in the coating, as these can reduce gloss. Use high-quality materials and monitor the thickness of the surface coating. Incomplete curing or improper temperature settings in the furnace can also lead to low gloss. Adjust paint dilution carefully and ensure the curing process is complete. Yuqi Metal follows strict process controls to deliver consistent gloss and high quality.

Mix paint well before applying.

Monitor coating thickness and curing temperature.

Use high-quality materials and avoid over-dilution.

Check for dust and ensure proper fineness in the coating.

Note: Regular inspections and process adjustments help you prevent low gloss and maintain the quality of your color-coated aluminum coils.

Delamination & Waviness

Defect Overview

Delamination and waviness are two defects that can impact the performance and appearance of color-coated aluminum coils. Delamination happens when the coating peels or lifts from the metal surface. Waviness, also known as oil canning, appears as buckling or uneven surfaces on the coil. These issues often result from improper surface preparation, moisture intrusion, or stresses during manufacturing. You need to understand the causes to prevent these defects and maintain high quality.

Here is a table that summarizes the main types and causes:

Defect Type | Description | Causes |

Coil Coating Delamination | Peeling or lifting of the paint or coating layer from the metal substrate. | Improper cleaning or surface prep before coating, Moisture intrusion during storage, Incompatible coating system. |

Oil Canning | Waviness or buckling in the flat surfaces of metal panels. | Stresses from manufacturing or coil slitting, Uneven fastener spacing during installation, Thermal expansion and contraction. |

Note: Delamination can expose the metal to corrosion, while waviness affects the flatness and visual appeal of the coil.

Identification

You can identify delamination and waviness through careful inspection. Visual examinations help you spot surface defects like peeling or unevenness. Dimensional checks allow you to measure physical properties and detect irregularities. These methods ensure you catch problems early and avoid further damage.

Inspection Method | Description |

Visual Examinations | Essential for identifying surface defects like delamination and waviness. |

Dimensional Checks | Helps in measuring the physical properties to detect irregularities. |

Tip: Always inspect coils under good lighting and use measuring tools to confirm flatness and coating integrity.

Prevention

Adhesion

You can prevent delamination by focusing on adhesion. Clean the aluminum surface thoroughly before applying the coating. Remove oil, dust, and moisture to create a strong bond. Choose compatible coating systems and follow manufacturer guidelines. Yuqi Metal uses advanced pretreatment and strict process controls to ensure reliable adhesion. Regular inspections help you detect early signs of delamination and take corrective action.

Clean and dry the surface before coating.

Use compatible coating materials.

Inspect for peeling or lifting during routine checks.

Rolling Parameters

Controlling rolling parameters is key to preventing waviness. Monitor tension, speed, and temperature during the rolling process. Adjust equipment settings to minimize stress and deformation. Yuqi Metal recommends routine equipment maintenance and process monitoring. You should check for uneven surfaces and make adjustments as needed. Proper rolling reduces the risk of waviness and keeps the coil flat.

Monitor tension and speed during rolling.

Adjust equipment to prevent stress and deformation.

Inspect for waviness after each production stage.

Callout: Consistent process control and regular inspections help you avoid defects and maintain the quality of your color-coated aluminum coils.

Precautions for Using Color-Coated Aluminum Coils

You can prevent defects and maintain quality by following key precautions for using color-coated aluminum coils. These steps help you avoid issues like crossbow, coil set, and center buckle. You protect your investment and ensure reliable performance in every application.

Handling

Proper handling is essential for preserving the integrity of color-coated aluminum coils. You must clean and treat the coils to remove impurities or contaminants. This step ensures the coating adheres well and lasts longer. You can use degreasing and deoxidizing methods to eliminate unwanted substances. Surface preparation, such as sanding or brushing, creates a smooth finish free from scratches or dents. Chemical pre-treatment enhances the bond between the coating and the aluminum.

Handling Procedure | Description |

Cleaning | Degreasing and deoxidizing remove contaminants, ensuring proper adhesion of the coating. |

Surface Preparation | Sanding, brushing, or grinding creates a defect-free surface. |

Pre-treatment | Chemical treatments or etching improve the bond between coating and aluminum. |

You can also choose moisture and salt-resistant coatings, apply extra layers for UV protection, and select materials that resist chemical corrosion. These precautions for using color-coated aluminum coils help you avoid common problems.

Tip: Always handle coils carefully to prevent scratches and dents. Use proper lifting equipment and avoid stacking coils directly.

Storage

You must store color-coated aluminum coils in optimal conditions to maintain quality. Indoor storage in a clean, dry, and well-ventilated warehouse is best. Allow coils to acclimate before unpacking, especially when moving from cold to warm environments. Use wooden pallets or rubber mats to prevent deformation. Adequate airflow around each coil helps moisture evaporate. Keep relative humidity below 50–60% to reduce condensation and corrosion risk.

Store coils indoors in a clean, dry, and well-ventilated warehouse.

Allow coils to acclimate before unpacking.

Use proper supports to prevent deformation.

Ensure airflow around each coil.

Keep humidity below 50–60%.

Handle coils carefully to avoid scratches.

Remove protective packaging film shortly before processing.

Inspect regularly for signs of damage or moisture.

These precautions for using color-coated aluminum coils ensure you avoid storage-related issues and maintain product quality.

Quality Inspection

You must perform thorough inspection to detect any defect before shipment. Coating thickness inspection confirms uniformity. Color consistency checks ensure the finish meets standards. Adhesion testing verifies the bond between coating and aluminum. T-bend or flexibility tests assess durability. Surface defect inspection, including visual inspection, helps you spot scratches, dents, or other irregularities.

Coating thickness inspection

Color consistency checks

Adhesion testing

T-bend or flexibility tests

Surface defect inspection

Note: Regular inspection and quality assurance measures help you deliver reliable color-coated aluminum coils. Yuqi Metal offers customer support and product customization to meet your specific needs.

By following these precautions for using color-coated aluminum coils, you minimize defects and maintain high quality. You can rely on Yuqi Metal for expert guidance and tailored solutions.

You protect your projects when you prevent defects and maintain quality in color-coated aluminum coils. Best practices and careful precautions help you avoid issues and improve performance. Ongoing training and regular inspections keep your team prepared. Yuqi Metal supports you with certified products and reliable service.

Certification Type | Details |

ISO 9001 | Management System |

FAQ

What are color-coated aluminum coils used for?

You use color-coated aluminum coils in construction, automotive, packaging, and HVAC industries. These coils provide both protection and decoration for roofs, walls, ceilings, and other surfaces.

How do you identify a surface defect on an aluminum coil?

You inspect the coil under good lighting. Look for scratches, dents, or color changes. Use a gloss meter or spectrophotometer for more precise checks.

Why does color difference occur in aluminum coils?

You may see color difference due to inconsistent raw materials, uneven coating thickness, or changes in process conditions. Always check batch numbers and monitor the coating process.

How should you store color-coated aluminum coils?

You store coils indoors in a clean, dry, and well-ventilated area. Use pallets or rubber mats. Keep humidity below 60%. Allow coils to acclimate before unpacking.

What is the best way to prevent poor adhesion?

You clean and pretreat the aluminum surface before coating. Use compatible coating systems. Monitor temperature and humidity during application for the best results.

Can you customize the alloy or finish with Yuqi Metal?

Yes! You can choose from various alloy series, thicknesses, widths, and surface finishes. Yuqi Metal offers customization to match your project needs.

How often should you inspect color-coated aluminum coils?

You should inspect coils before and after storage, during handling, and before use. Regular checks help you catch defects early and maintain quality.

Who can you contact for technical support or product advice?

You can contact Yuqi Metal’s customer support team. They provide expert guidance, technical information, and help with product selection.