Aluminum circle (also called aluminum disc or wafer) is a processed product made from aluminum sheets or coils through cutting and blanking. With properties such as excellent heat dissipation, electrical conductivity, corrosion resistance, light weight, and long service life, aluminum discs are widely favored for cookware, appliances, lighting fixtures, and road traffic signs.

YUQI Metal provides both CC (Cold Rolled) and DC (Hot Rolled / Deep Drawn) aluminum circles, ensuring reliable performance for various forming processes including deep drawing, spinning, stamping, and anodizing.

![DISC1 DISC1]()

Key Advantages

High thermal conductivity – excellent heat dissipation for cookware and appliances.

Lightweight & durable – reduces overall weight while maintaining strength.

Good corrosion resistance – natural oxide film plus optional surface treatment.

Excellent processability – suitable for deep drawing, spinning, stamping.

Wide alloy selection – 1000 / 3000 / 5000 / 8000 series available.

Custom sizes – diameter, thickness, and temper can be tailored to customer needs.

Strict QC & certification – every disc undergoes inspection for thickness, diameter, and surface.

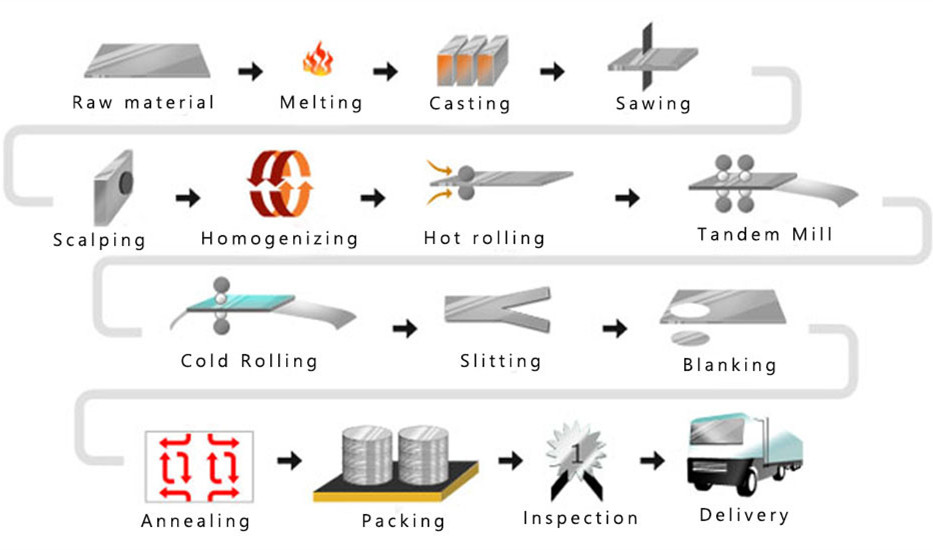

Manufacturing Process

✅ Raw Material → Melting → Casting → Sawing

✅ Scalping → Homogenizing → Hot Rolling → Tandem Mill

✅ Cold Rolling → Slitting → Blanking (Circle Cutting)

✅ Annealing → Packing → Inspection → Delivery

This process ensures smooth edges, consistent thickness, accurate diameters, and excellent surface quality suitable for further finishing (anodizing, coating, polishing).

![DISC2 DISC2]()

1. Raw Material: High-purity aluminum ingots are carefully selected to guarantee excellent formability, conductivity, and corrosion resistance.

2. Melting: The aluminum ingots are melted in a high-temperature furnace to remove impurities and ensure a uniform chemical composition.

3. Casting: The molten aluminum is cast into solid slabs or billets, which serve as the base material for rolling.

4. Sawing: Cast slabs are cut into the required dimensions to prepare them for further rolling and processing.

5. Scalping: The surface layer of the slab is machined off to remove defects and ensure a smooth, uniform surface.

6. Homogenizing: Heat treatment is applied to the slabs to improve internal structure, relieve stress, and enhance mechanical properties.

7. Hot Rolling: The homogenized slabs are hot rolled into thinner plates, improving their mechanical strength and elongation.

8. Tandem Mill Rolling: Continuous rolling is performed to further reduce thickness and improve flatness and surface quality.

9. Cold Rolling: After hot rolling, cold rolling is applied to achieve precise thickness control, improved surface finish, and higher strength.

10. Slitting: The rolled aluminum sheets are slit into narrower strips to meet customer requirements and prepare for circle blanking.

11. Blanking (Circle Cutting): Round discs are punched or cut out of the aluminum sheets with high precision, ensuring smooth edges and accurate diameters.

12. Annealing: Heat treatment (annealing) is applied to restore ductility and ensure excellent deep-drawing performance, critical for cookware and lighting applications.

13. Packing: Finished aluminum circles are tightly packed with moisture-proof materials and strapped securely on pallets to ensure safe transportation.

14. Inspection: Every batch undergoes strict quality inspection for thickness, diameter, surface finish, tolerance, and mechanical properties.

15. Delivery: After inspection and certification, the final products are delivered to customers worldwide.

Classification & Applications

1. Cookware Aluminum Circle & Disc

Common alloys: 1060, 1100, 3003

2.0–3.0 mm, 1060 O/H12 → frying pans, pizza pans, electric frying pans

2.0–4.0 mm, 3003 O → electric pressure cookers, rice cookers

0.7–2.0 mm, 1100 O → stock pots, general kitchenware

3.0–5.0 mm, 1100 O → cooker bottoms, stainless steel clad bases

Advantages: Good heat conduction, lightweight, easy for deep drawing and spinning.

![C003 C003]()

2. Lighting Aluminum Circle & Disc

Lighting aluminium circle is mainly used to produce lampshade. It can also be used for embedded lighting, high shed industrial lighting, low shed industrial lighting, traffic light reflector and sports lighting.

Common alloy: 1100 O

0.5–1.5 mm, 1100 O → standard lamp shades

0.5–1.5 mm, anodized 1100 O → high reflectivity ≥65%, semi-mirror finish after bright dipping, ideal for decorative lighting

0.5–5.0 mm, coated 1100 O → coated lamp shades, industrial lighting reflectors

Applications: Embedded lighting, industrial high/low bay lighting, traffic light reflectors, sports lighting.

![C004 C004]()

3. Road Sign Aluminum Circle & Disc

Currently, it is mainly used to supervise traffic signs, warning traffic signs, guidance signs, etc

Common alloy: 1100 H14

Applications: Regulatory traffic signs, warning signs, guidance and direction boards.

![C005 C005]()

YUQI Alloy Series & Properties of Aluminum Circle and Disc Stock

Aluminum circle and disc of 1000 series

Alloy: 1050, 1060, 1070, 1100

Features: >99% pure aluminum, excellent formability, high reflectivity

Application: common cookers, extruded pot covers, aluminum pots, lamp accessories, lampshades, downlights, laminated lamps, street lamps, signs and building materials, traffic signs, curtain walls, ceilings.

Aluminum circle and disc of 3000 series

Alloy: 3003, 3004, 3105

Features: high elongation, can be used for deep drawing, high grain size, smooth surface, high reflectivity

Application: high grade cookers, sticky pans, pressure cookers, lamp accessories, signs and building materials

Aluminum circle and disc of 5000 series

Alloy: 5052, 5754, 5083

Features: low material density, light weight of finished products, high tensile strength and elongation, and good fatigue strength

Application: Non stick pan, pressure cooker, pressure vessel, pressure cooker, etc.

Aluminum circle and disc of 8000 series

Alloy: 8011

Features: excellent anodizing effect, stable performance and high surface quality

Application: pearl anodized cookware, decorative anodized lighting

Related Trend and Video

Aluminum circle disc is a product of aluminum plate after deep processing. Hot rolled aluminum discs are widely favored by the market. The electric appliances, pots and other products produced by hot rolled aluminum discs have the advantages of good heat dissipation, good conductivity, corrosion resistance, light material and long service life.

Using the characteristics of hot rolled aluminum wafers have good heat dissipation, good conductivity, corrosion resistance, light material and are easy to use for a long time.

FAQ

Q1: What is the difference between CC and DC aluminum circles?

A: CC (Cold Rolled) is more economical for general use. DC (Deep Drawn / Hot Rolled) offers superior surface and formability, recommended for cookware and lighting.

Q2: What diameter range is available?

A: From 50 mm up to 1200 mm, customized according to customer drawings.

Q3: Can the discs be anodized or coated?

A: Yes, discs can be supplied mill finish, polished, anodized, or coated depending on application.

Q4: What is the MOQ and lead time?

A: MOQ usually starts from 1 ton. Delivery is 7–10 days for stock sizes, 15–20 days for customized orders.